|

Batteries

Delcotrons

Heated Windshield

Heavy Duty

Horns

Ignition

Magnequench

MISAR

Missile Battery

Propulsion Systems for Electric Vehicles

Regulators

Shock Absorbers

Starters Switches

Remy Brother Patents

Products

Horns

Delco-Remy got into the horn

business in

1924 with the purchase of the Klaxon Horn

Company in Newark, NJ. It had been determined that Remy could build

the horn at a lower cost than Klaxon and the manufacturing equipment was

moved from New York to the third floor of Plant One, where horn

manufacture remained until 1946 when it moved to Plant 7. The

manufacture of horns remained there until it moved to Plant 10 in the

1980's. This was its last location until the product line was sold

in the late 1990's.

When the windows were open during

the summers when the horns were in Plant One (This before the the Plant

was air conditioned and sound booths were used to capture the sound.

Link to 1940 Anderson Library Photo) one could hear the horns being

blown during test within a radius of several blocks of the plant.

Below is a progression of the design evolution of Delco-Remy horns which

were on all GM cars and light duty trucks from 1924 until the late

1990's..

The Klaxon

Horn. A Klaxon type horn uses a motor-driven toothed wheel which

ratchets against a metal stud attached to a diaphragm. Later horns would

remove the motor and have the diaphragm activated by magnetic field

from a coil of magnet wire. Cost of a Klaxon horn was $3.50. Photo courtesy of Ted Vinson / Madison County

Historical Society.

Link to YouTube Delco-Remy KLAXON 8C Ahooga Horn

Link to YouTube Delco

Remy Klaxon 6 Volt Horn Model 8C

This was known as a Sea Shell Horn and

replaced the Klaxon design. Even after the Klaxon design was

replaced the term "Klaxon" was still used to mean an automotive horn.

Photo courtesy of Ted Vinson / Madison County Historical Society.

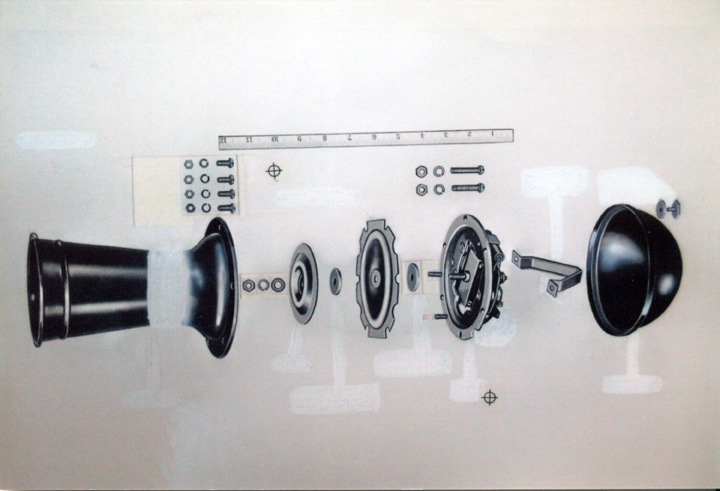

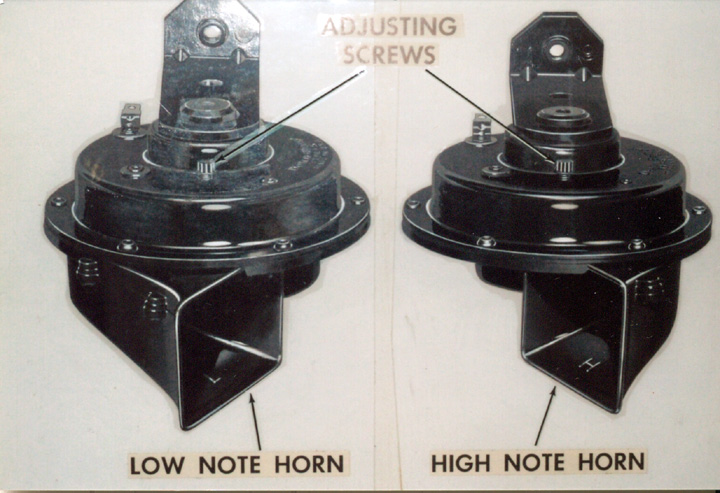

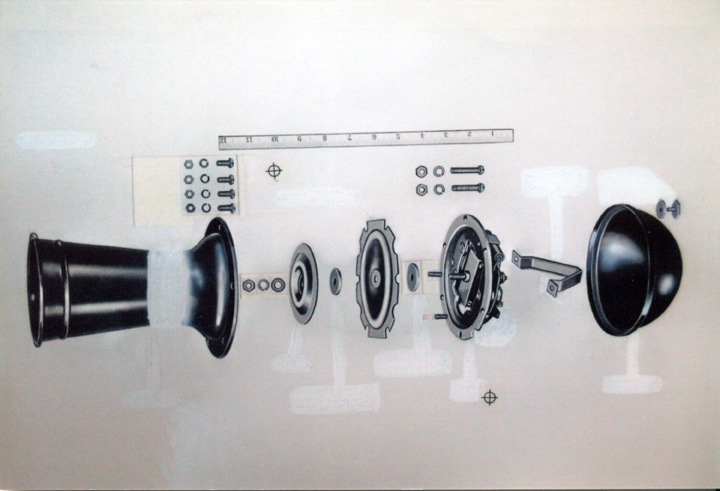

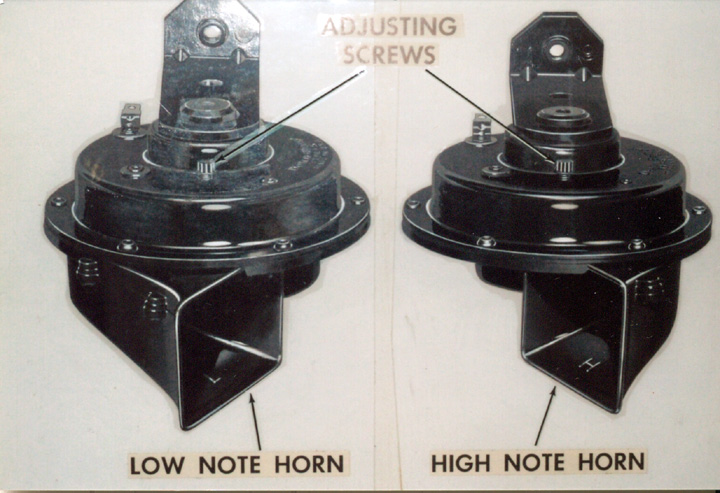

Aluminum Die cast Horns were next in the

series. Later one there were five horn notes that were manufactured. Photo courtesy of Ted

Vinson / Madison County Historical Society.

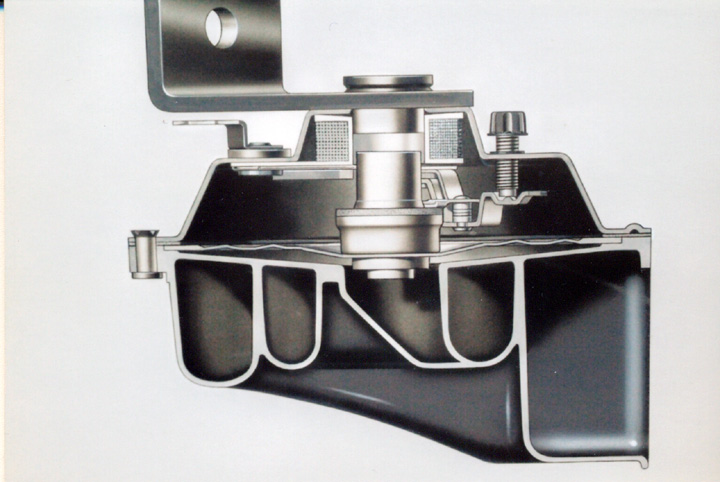

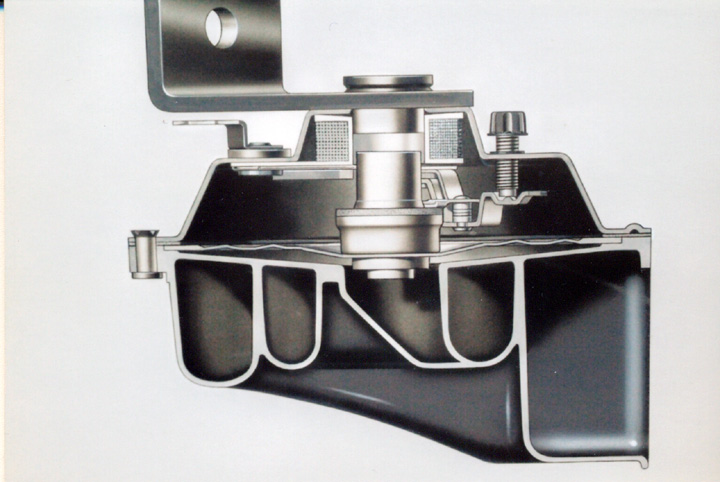

Cross section of a die cast horn. Photo

courtesy of Ted Vinson / Madison County Historical Society.

Plastic Horns that were introduced in

1974 and resulted in four new production lines in Plant 7. The

projector was plastic while the back shell and back plate were stamped

steel. Gene Phillips.

While there were only five

notes that horns produced there were literally hundreds of horn brackets

for mounting the horns to vehicle as every GM vehicle had its own unique

location for the horn or horns causing a proliferation of part numbers. Horns

were also typically the last component that were found room for under the

hood during the vehicle design resulting many times with them being placed down

very low in the engine bay. This would increase warranty

claims as water and salt would get into the horn, corrode it and cause it

to fail. If relocated to a higher location the problem would go away

or be reduced. In any location under the hood the horn would

be oriented with the projector opening down to allow for drainage of moisture.

The last series of horns were produced in five

musical notes which could be used individually or in combination to give a

musical chord. Below are 1978 GM horn applications. Note that

GMC or Chevy trucks are not included below although they had DR horns also. The Alarm Tone produced a piercing sound

as part of the Corvette Anti-Theft System.

| Lo-Tone "F Note" |

Hi-Tone "A Note" |

Deep-Tone "D Note" |

Penetone "High C Note" |

Alarm Tone "High F Note" |

| Buick |

Buick (except Skylark) |

Buick (optional on

Electra, LeSabre, Riviera) |

Buick (optional on

Electra, LeSabre, Riviera) |

|

| Cadillac |

Cadillac Seville (all

others optional) |

Cadillac (except Seville) |

Cadillac Seville (optional

for all others) |

|

| Chevrolet (except

Corvette, Chevette) |

Chevrolet Chevette,

Camaro, Nova, Malibu, Corvette, Monte Carlo |

Chevrolet Caprice |

Chevrolet Corvette |

Chevrolet Corvette (optional on Van) |

| Oldsmobile |

Oldsmobile Cutlass, Omega |

Oldsmobile98, 88 Toronado |

|

|

| Pontiac |

Pontiac (except Sunbird)

(standard LeMans) |

|

|

|

Proposed Electronic Horn that never went into

production. Gene Phillips photo.

|