|

Batteries

Delcotrons

Heated Windshield

Heavy Duty

Horns

Ignition

Magnequench

MISAR

Missile Battery

Propulsion Systems for Electric Vehicles

Regulators

Shock Absorbers

Starters Switches

Remy Brother Patents

Products

Batteries

Information on

Batteries supplied by Doug Grinstead.

This was not only first battery

built in Muncie but also the first one built by Delco-Remy. It could

have been built in Anderson on the location of Plant 8 if the citizens of

Anderson would have been more willing.

The Delco Energizer Battery introduced 1966

was the first to replace rubber battery cases with plastic cases and

one piece top covers. Also included in the new design are through

the wall cell connectors and the Delco Eye for determining battery charge

state. The battery had 16% more power than previous designs.

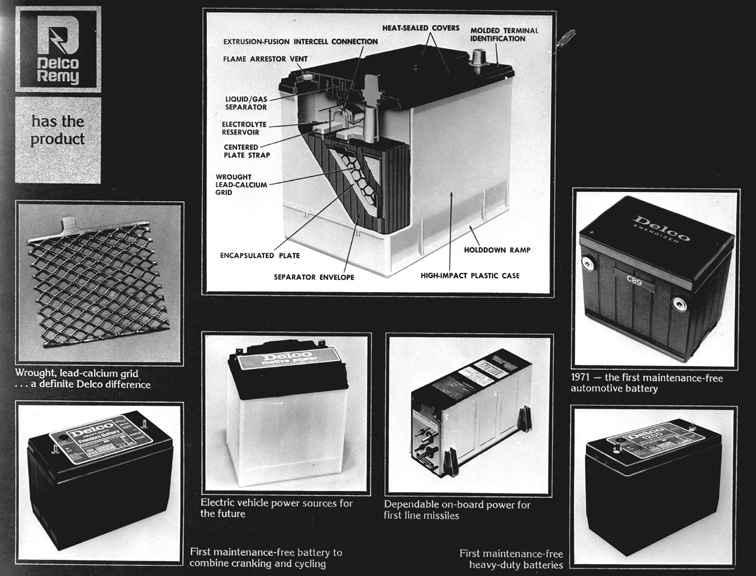

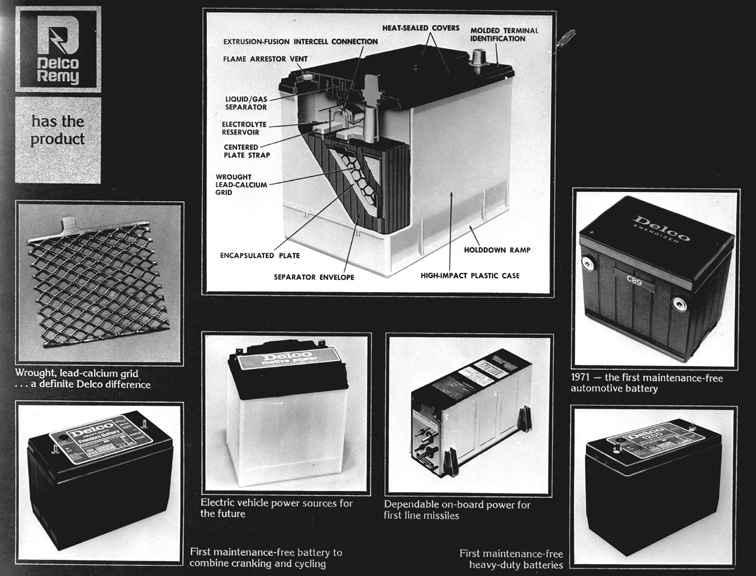

This photo shows a collection of

maintenance-free (MF) batteries manufactured at DR. Clockwise starting

with the 12:00 position is an example of our MF HD battery for

semi-tractor trailers and other HD applications. Next is a Delco Voyager

for marine (or RV) applications that require a long reserve capacity to

run trolling motors, etc. Next is an aftermarket replacement battery for

automotive use. The 72 represented the number of months the battery

was warranted for. The handle was added for easy carrying and

installation. The next battery is a replacement battery for European

nameplate autos. The next battery is the original equipment side

terminal battery for GM autos. Gene Phillips photo.

This shows another example of our very

successful HD MF battery for over the road semi-tractor trailers,

bulldozers and other construction equipment. Gene Phillips photo.

This aftermarket battery brand was targeted

for trucks and vans. The label is interesting in showing the DR brand.

Most of our aftermarket batteries were marketed under the Delco Freedom

brand. Gene Phillips photo.

This

battery is a low-cost aftermarket brand. The 55 represents the BCI

(Battery Congress International, an industry organization) group size that

was supposed to be common across all manufacturers. Gene Phillips

photo.

This

photo highlights some of the design features that distinguished the DR

battery from our competitors. Gene Phillips photo.

This photo shows an unlabeled aftermarket dual terminal battery

with a handle to make it easy to carry and install. The detachable

adapter on the top cover could be used as a spacer underneath the battery

if required for a better fit. This battery was designed and marketed as

an almost universal fit for any vehicle.

Gene

Phillips photo.

|