|

Delco-Remy in WWII

Delco-Remy WWII Aircraft

Products

Delco-Remy WWII Marine

Equipment

Delco-Remy WWII Tank Products

Delco-Remy WWII Vehicle Products

Delco-Remy and LST-393

Delco-Remy WWII King's Mill

Plant

Delco-Remy WWII Antioch

Foundry

Delco-Remy WWII Stationary Engine Products

Delco-Remy WWII

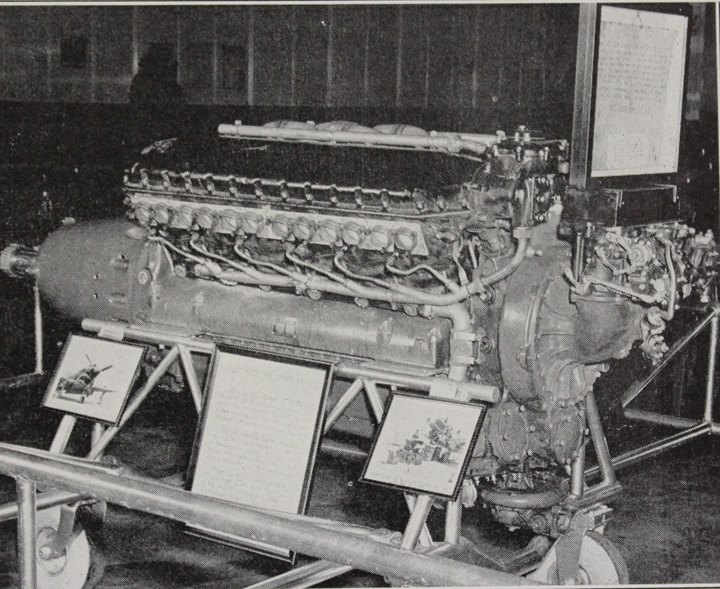

Electrical Components for the Reo and Federal Truck, 20-Ton, 6x4

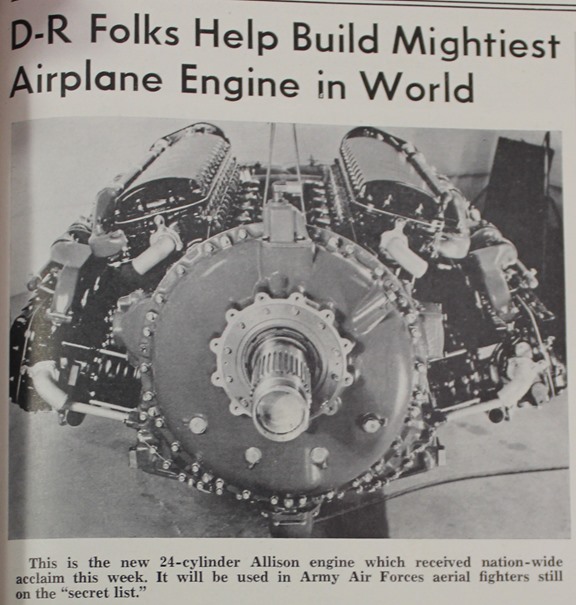

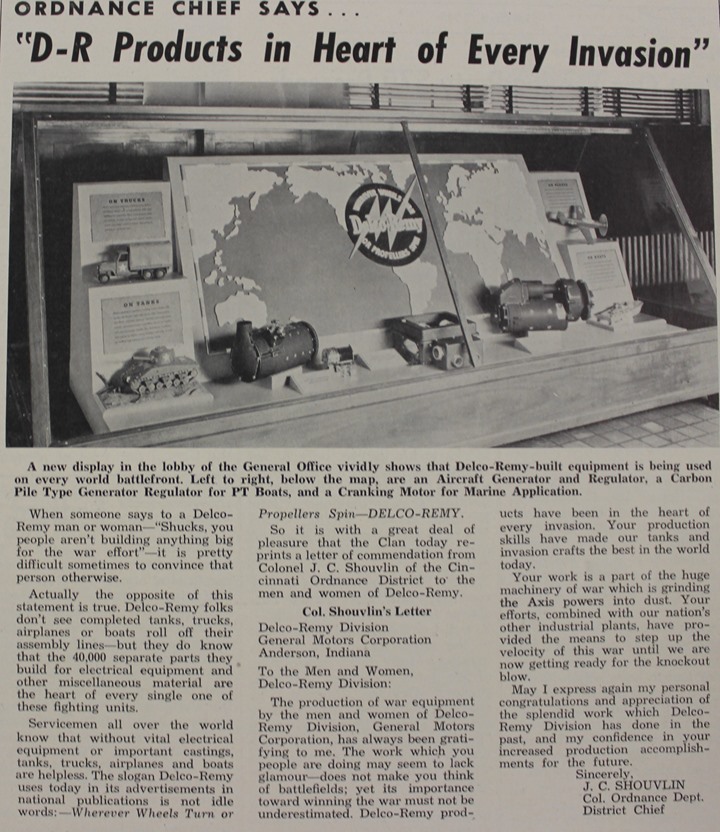

Delco-Remy Training Manuals for Aircraft Components This is one of four pages on this site to exhibit the contributions of Delco-Remy Division of GM in winning the Second World War. "Delco-Remy at the Normandy Invasion" details the contribution of the Division during this historic amphibious invasion. "Our War Job" is the complete reproduction Delco-Remy's 1944 booklet detailing its participation in the war effort up to that date. "The Army-Navy "E" Award with Three Stars" page is a photo essay of Delco-Remy's World War Two "E" flag. This page, "World War Two Products and Product Applications," complements the other three pages, by providing more detail on the many weapons which used Delco-Remy electrical components. Many of these weapons were not at the Normandy Invasion. They were either introduced into the European combat zone after the initial landings, or obsolete as front line fighting weapons prior to D-Day. This page has eight more pages linked at the top that provide more extensive information on Delco-Remy World War Two products and their applications. There is too much information to add to one page. Prior to World War Two, Delco-Remy not only supplied General Motors cars and trucks with electrical components, but also supplied other car and truck makers as well. Even before the United States entered World War Two after Pearl Harbor, Plant 7 was built in 1940 as an aluminum foundry to produce castings for the Allison V-1710 aircraft engine. This page shows many of Delco-Remy (D-R) products used in a plethora of military applications during World War Two. Product applications fell into four basic groups: trucks, tracked and wheeled armored vehicles, small boats and landing craft, and aircraft engines and equipment. The information on this and the other eight related pages is not comprehensive but what is known of applications for Delco-Remy products during World War Two. There were so many, and after 80 years, it is difficult to find all of the war products D-R built. This, and the associated application pages, are a good snap-shot of how Delco-Remy helped win World War Two.

Delco-Remy

World War Two Production Numbers: During World War Two, companies were

not allowed to publicaly publish production numbers. as they were

considered to be a military secret. In 1945 these regulations

eased up. In the February 9,1945 edition of the "Delco-Remy Clan,"

Delco-Remy was allowed to release production numbers of WWII products to

date. The numbers are by general product groupings and not by

individual product; but they do give an insight into the amount of war material D-R

produced up until early 1945.

PT-305:

LST-393:

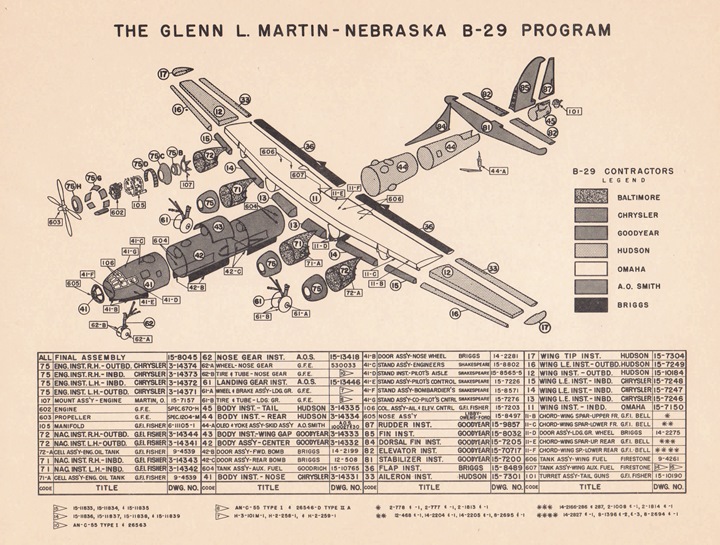

The B-29 Project: Delco-Remy was one of seventeen GM Divisions that built components for the B-29. It was the most expensive project of WWII, being even more expensive than the Manhattan Project. No mention of the B-29 is made in the 1944 Delco-Remy booklet "Our War Job". There are two reasons for this. First, production on the B-29 did not start until mid-1944, and contracts and tooling were still being made when the booklet was published. Second, the B-29 project was considered "Top Secret." Delco-Remy would have only been able to state it was working on the project, but not what the project was. As diverse as Delco-Remy produced aircraft-related products were during World War Two, the Division could have supplied any number of components for the B-29.

Starting at the front of the fuselage and working towards the rear of the aircraft, the glass nose section was built by Libby-Owens-Ford, an automotive glass company. The fuselage nose section was built by Chrysler's Plymouth Division in Detroit. Goodyear in Akron, OH built the two bomb bay fuselage sections. Briggs, an independent auto body manufacturer in Detroit, provided the bomb bay doors. The three rear fuselage sections behind the wings were also built in the city of Detroit by the Hudson Motor Car Company, which combined with Nash in 1954 to become American Motors. The entire tail section and the elevators with control surfaces were made by Goodyear, and the tail gunner's position was manufactured by the Fisher Body Division of GM at Cleveland, OH. Martin Omaha provided the center section of the wing. Chrysler provided the inboard leading edges. Hudson built the outer wing sections, outer leading edges, ailerons, and wing tips. Briggs provided the flaps. All four engine nacelles and engine oil tanks came from the Fisher Body Division of GM along with the exhaust manifolds. Omaha built the engine mounts; Dodge supplied the engines and Chrysler the engine cowlings. Firestone provided the main and auxiliary wing fuel tanks. BF Goodrich provided the fuselage auxiliary fuel tank. While this is a Boeing-designed aircraft, there are no major fuselage, wing nor rear tail section components provided by that company for the Martin Omaha-built B-29s. With the exception of the Martin wing center section, the rest of the wing was supplied by the American automobile industry. Inside the B-29 airframe and wing structural components listed above, there were tens of thousands of parts and components. The engine nacelles produced by the Fisher Body Division of GM had over 3,000 parts in them. Each nose fuselage section built by Chrysler had 5,000 parts in it. Many of the parts for many of the major components would have been supplied by AC Sparkplug, Allison, Brown-Lipe-Chapin, Buick, Chevrolet, Delco Appliance, Delco Products, Delco Radio, Delco-Remy, Fisher Body, Frigidaire, Harrison Radiator, Hyatt Bearings, Moraine Products, New Departure, Packard Electric, and Rochester Products Divisions of GM as identified in the 1944 GM Annual Report. Of significance is that the Martin Plant in Omaha, NE produced the Silverplate B-29 Nuclear Bombers.

Delco-Remy World War Two Products: Electrical Components for Military Trucks - Generators and generator regulators, starting motors, ignition distributors and coils, switches, and batteries; Electrical Components for Military Tanks and Armored Vehicles - Generators and generator regulators, starting motors, ignition distributors and coils, apparatus boxes, and batteries; Electrical Components for Military Aircraft - Generators and generator regulators, magnetos, and batteries; Automatic Aircraft Engine Controls; Solenoids for Sperry Autopilots; Automatic Trim Tab Controls; Electrical Components for Military Marine applications - Generators and generator regulators, starting motors, ignition distributors and coils; Marine propeller pitch controls for landing craft and submarine chasers; Marine diesel equipment - pistons, blowers, pre-heaters and pre-heater fuel pumps, governors; Tubing - for electrical, fuel, brake, air conditioning, oil and air lines; Allison V-1710 engine castings - Various; Aircraft engine machined parts - Various; (1,000,000) 20mm shell bodies; Various solenoids for starting motors, aircraft bomb release racks, guns and overdrive controls.

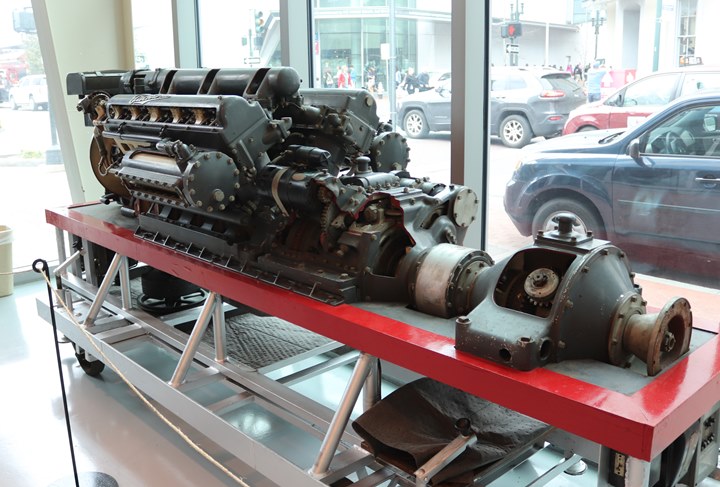

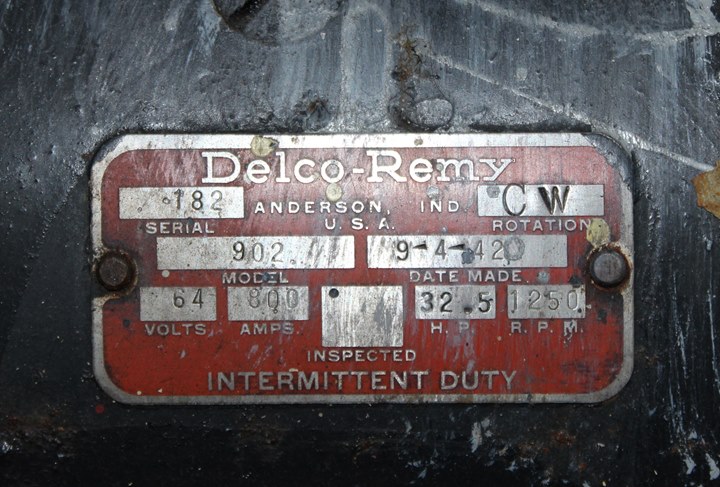

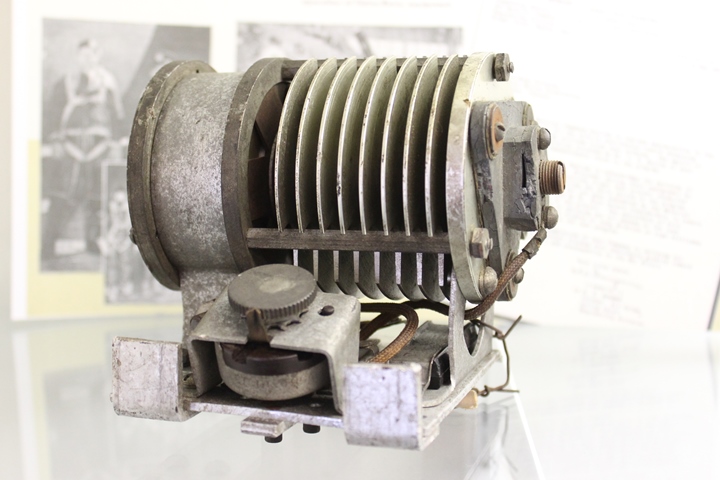

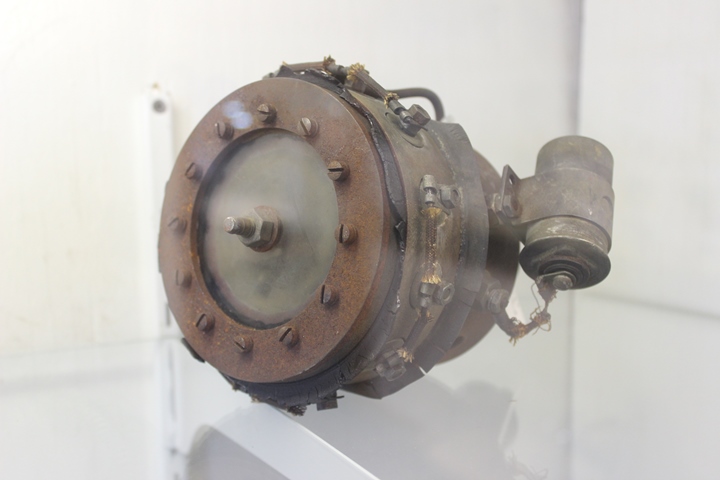

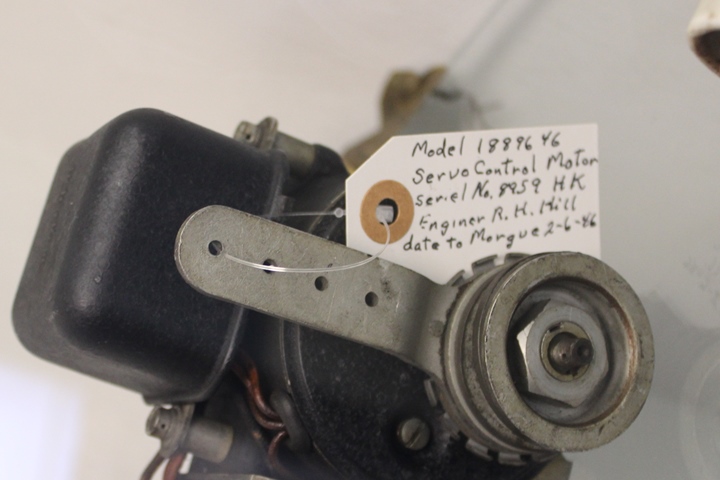

Delco-Remy World War Two Products at the Madison County Historical Society: The Madison County Historical Society in Anderson, IN has an excellent collection of Delco-Remy-built World War Two era components. Below are photos from the 2016 Delco-Remy exhibit at the historical society. Some of the parts are experimental, and others production items.

World War Two Experimental Alternator: This Delco-Remy engineering sample was found on the 1943 Chevrolet Airborne Extra-Light 1/4-Ton Jeep Program. More photos and information can be found on the Delco-Remy Military Truck page.

'Delco-Remy Clan' Photos:

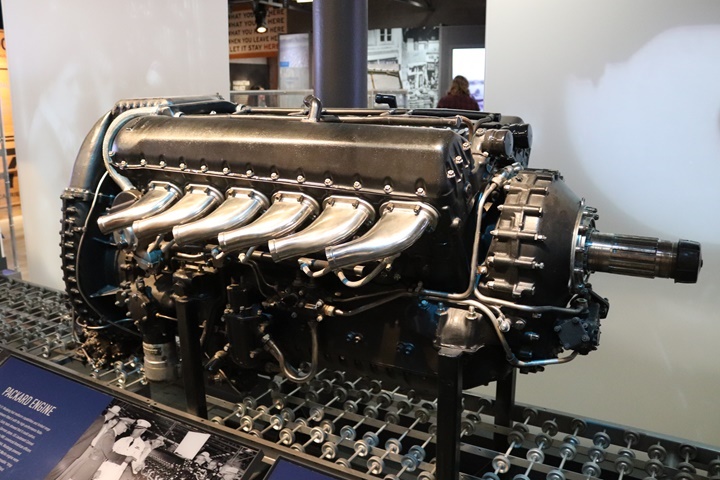

According to the March 9, 1945 edition of the 'Delco-Remy Clan,' Bedford had received new contracts for increasing production on the Rolls-Royce aircraft engine. This implies that Bedford had already been producing casting for the Packard-built Rolls-Royce V-1650 Merlin engine. This is the only reference I have ever seen that Delco-Remy was supplying castings to any other aircraft engine manufacturer besides Allison. The Packard-built Merlin engine was the most important and best engine used in an Army Air Force fighter during World War Two. It made the P-51 Mustang into the best Army World War Two fighter aircraft.

Kings Mill, OH:

On April 28, 1944 it was announced that the U.S. Navy had taken control

of the former Kings Mill Army Ordnance plant in Kings Mill, OH, and that

Delco-Remy would build cranking motors for diesel powered landing craft.

By the end of the war, in just a year's time, the plant had produced

64,000 naval cranking motors and 375,000 switches. This was done

with a work force of 900 employees. Today the former location of the plant is contained within the grounds of an Army Reserve Center.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||