|

Delco-Remy in WWII

Delco-Remy WWII Aircraft

Products

Delco-Remy WWII

Marine Products

Delco-Remy WWII Tank Products

Delco-Remy and LST-393

Delco-Remy WWII Kings Mills Plant

Delco-Remy WWII Antioch

Foundry

Delco-Remy WWII

Stationary Engine Products

Delco-Remy WWII

Electrical Components for the Reo and Federal Truck, 20-Ton, 6x4

Delco-Remy

Training Manuals for Aircraft Components

Delco-Remy in

World War Two

World War Two

Products and Product Applications

Components for

Military Trucks and Tractors

This page updated

12-18-2024.

Delco-Remy Truck Equipment in World War Two:

Forty-four models of generators, 21

models of regulators, 36 models of starting motors, 31 models of ignition

distributors, 10 models of ignition coils, 3 models of storage

batteries, and 65 starting, lighting, and ignition switches for Chevrolet

and GMC trucks. This amounted to 831,546 vehicles.

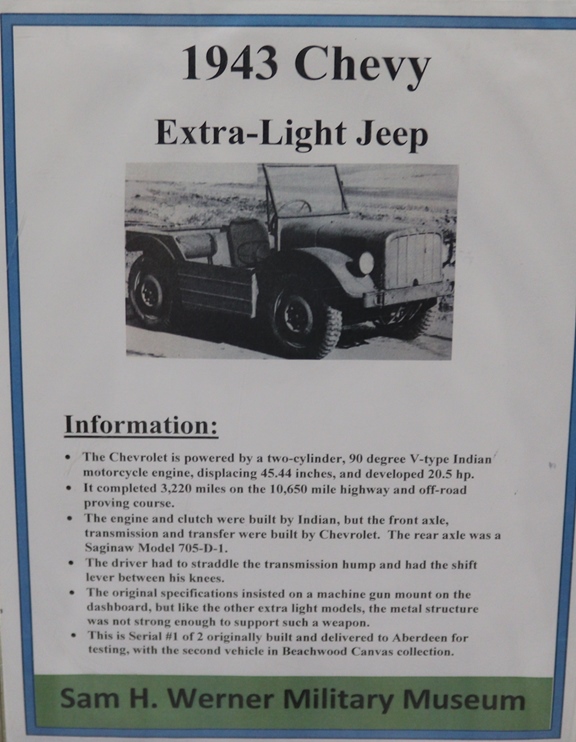

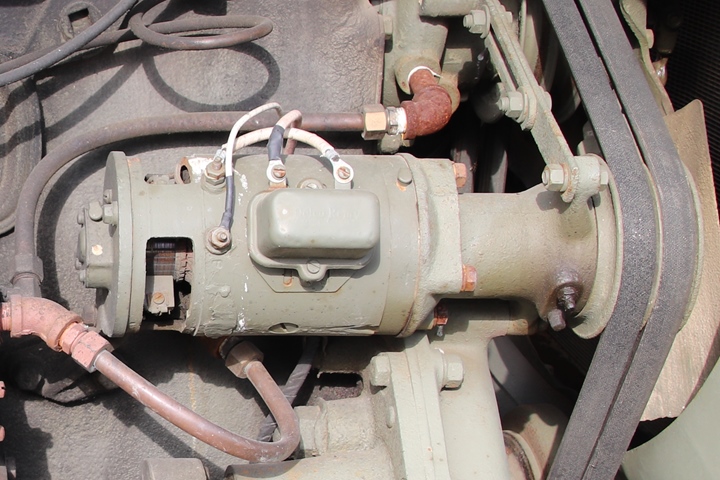

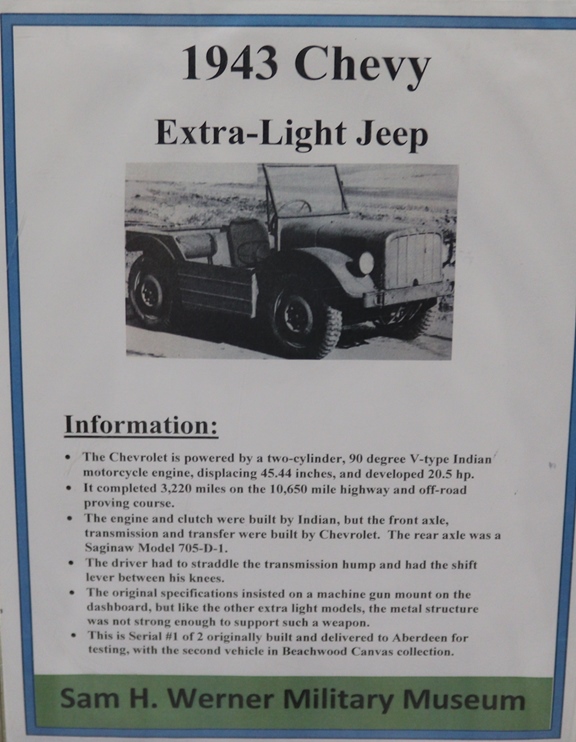

The Airborne Extra-Light 1/4-Ton Jeep

Program: This 1942-43 program was initiated during World War

Two to develop a lighter version of the standard 1/4-ton jeep which could

be parachuted into a combat zone. Six companies developed samples

for U.S. Army testing. The Chevrolet entry had a Delco-Remy

experimental electrical component installed on an Indian motorcycle

engine. The component appears to be an alternator.

Author's photo added 5-11-2020.

Author's photo added 5-11-2020.

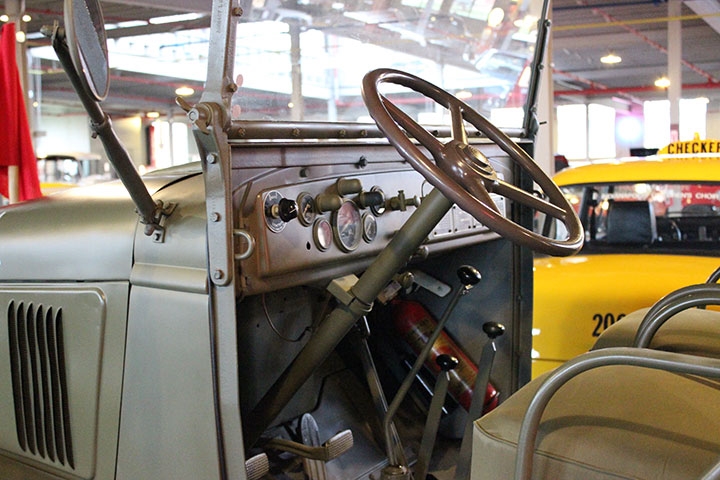

The Delco-Remy engineering sample is set in

the center of the engine bay. Author's photo added 5-11-2020.

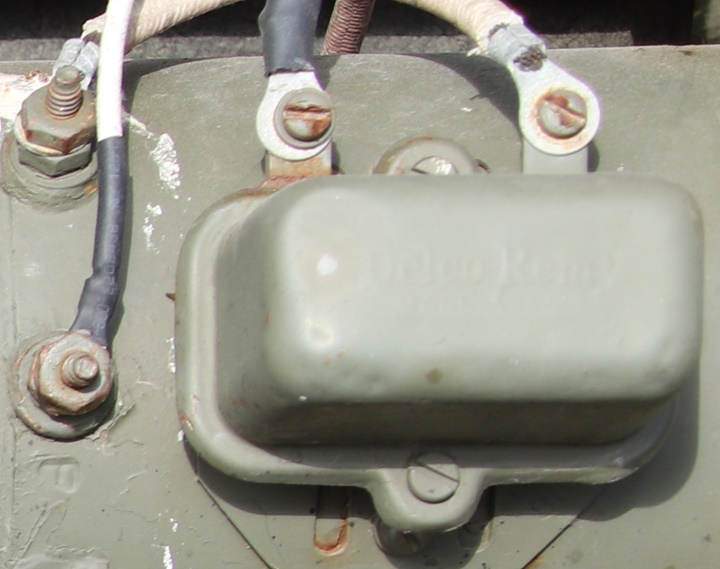

A closer look shows this to be a rotating

device with a pulley and fan similar to the Delco-Remy alternators

introduced 19 years later in 1962. The three output wires go to the

voltage regulator on the fire wall, as shown in the photo above. It

appears that Delco-Remy did initial work on experimental alternators during

World War Two. Author's photo added 5-11-2020.

An alternator was a

lighter weight option than a DC generator for the extra-light jeep

program. However, the unit produces an alternating current which

needs to be rectified into direct current for use in the vehicle.

Bell Labs did not invent the transistor nor semiconductor diode until 1948. It took the intervening years to develop the technology

and manufacturing capability to furnish the six diodes each alternator

would need.

If this was actually an

alternator to reduce weight in the extra-light jeep, the rectifying

circuit would have been vacuum tubes. There are three wires

running from the output of the alternator to what looks like the voltage

regulator. This would imply that the three-phase current is being

directly output to the regulator. There does not appear to be any

electrical box for six vacuum tube rectifiers. Vacuum tubes to rectify the AC

would have taken up a lot of space, added weight, and generated heat.

There is still a mystery to this unit.

Author's photo added 5-11-2020.

Chevrolet: Chevrolet built 281,570 1/2 ton, 3/4 ton and

1-1/2 ton trucks in both 4x2 and 4x4 configurations. Among these

were trucks that bored holes for telephone poles. Others were

ambulances, pickups, fire and crash trucks, cargo, and dump trucks, to

name a few of their many uses. Different trucks with

different applications would have had different electrical requirements.

As early as 1940, Delco-Remy provided

electrical components to Chevrolet military trucks. This is

a Chevrolet 1-1/2-ton dump truck. Author's photo added 5-11-2020.

This is a 1941 Chevrolet 1-1/2-ton military

cargo truck with Delco-Remy components. Author's photo added

5-11-2020.

This 4x4 Chevrolet hole borer was one of the

more popular applications of the Chevy truck during World War Two. Author's photo.

One application for the Chevy 1-1/2 ton 4x4

truck was this bomb truck. Author's photo.

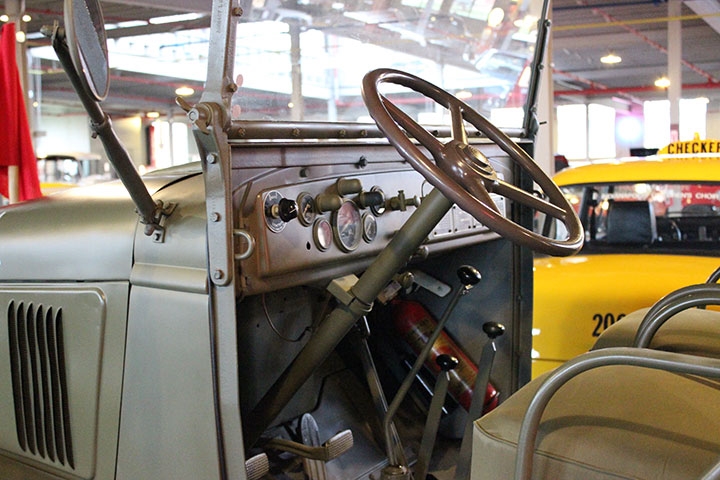

Several of

the D-R switches are on the instrument panel. The starter and headlight dimmer switches were

mounted on the floor. Delco-Remy also supplied

the battery, generator, regulator, starter, ignition coil, and distributor. Author's photo.

Chevrolet also built military crash trucks like this one.

Author's photo.

The horn is no doubt the famous Delco-Remy

Klaxon. Author's photo added 5-11-2020.

Chevy trucks had Delco-Remy

voltage regulators mounted on the fire wall in

front of the driver. Author's photo.

GMC: GMC and Chevrolet

manufactured 528,829 GMC 6X4 and 6X6 2-1/2 ton military trucks in

various configurations. All of these had Delco-Remy electrical components.

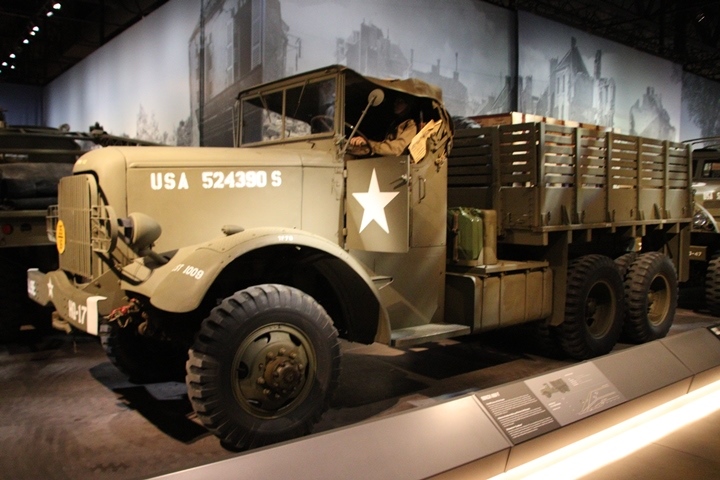

One of the more rare models of GMC World

War Two 2-1/2 ton 6x6 trucks with D-R electrical components is this AFKWX cab over engine with an extended

cargo bed. This design allowed for a longer cargo bed for high

volume loads. Author's photo.

GMC 2-1/2-ton 6x6 fuel and oil trucks

were used at airfields around the world during World War Two. Author's photo.

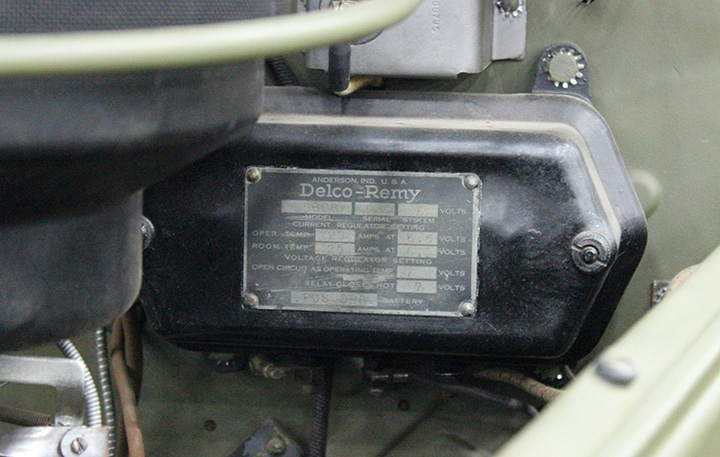

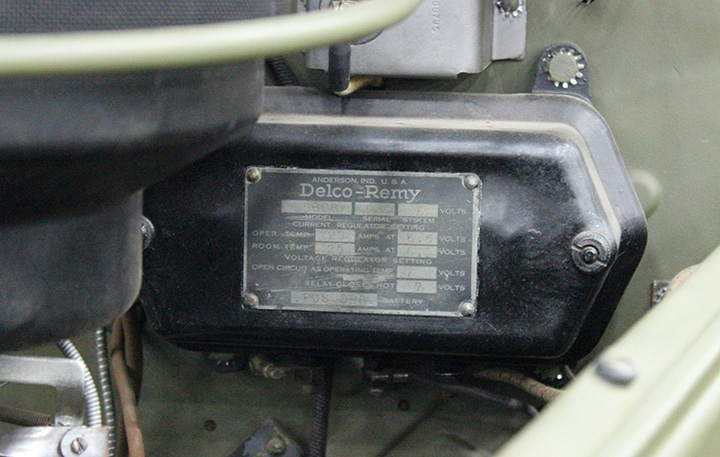

This Delco-Remy 6-volt regulator is inside the engine bay of the GMC.

This is model number 5628 and serial number 56554. Author's photo.

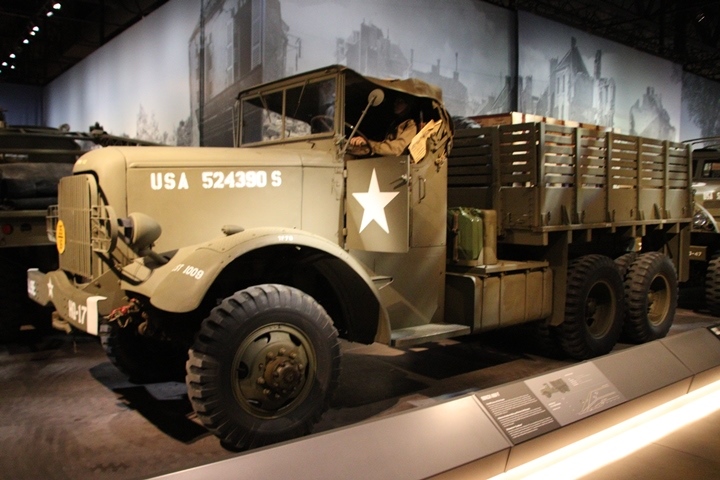

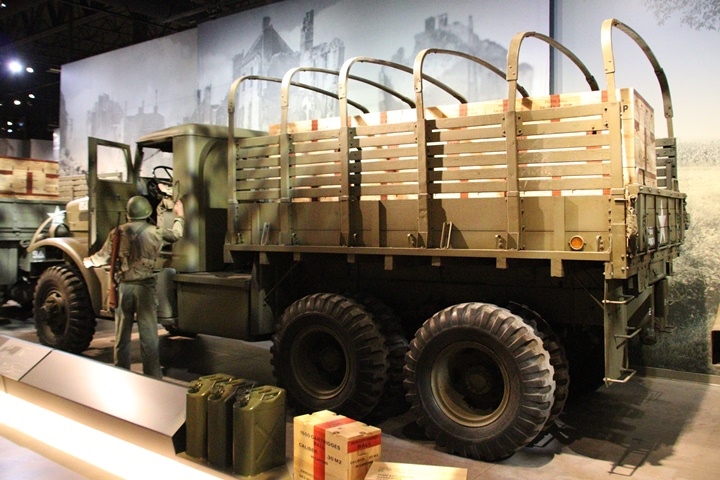

This cargo version of the GMC was the

most prevalent. Author's photo.

GMC and Chevrolet built 21,147 GMC-designed DUKW

amphibious trucks, like the one seen

here. Due to the fact that the DUKW worked in a marine

environment, Delco-Remy supplied electrical equipment that was resistant

to salt-water corrosion. Author's photo.

General Motors of Canada built 201,000

Canadian Military Pattern (CMP) trucks during World War Two with

Delco-Remy electrical components. The

Canadian military required both General Motors and Ford to build the

same basic vehicle for standardization. The CMP trucks were based on a

British 15-cwt vehicle. The GM of Canada versions were Chevrolets,

as denoted by the bowtie on the grill. The GM of Canada CMP

vehicles were

powered by Chevrolet 85 hp engines. Author's photo added

12-1-2020.

The CMP trucks were right hand drive.

This one has a transport body on it. Author's photo added

12-1-2020.

The trucks came with various bodies to be

used for

different tasks. This one has a radio body on it. Author's

photo added 12-1-2020.

Non-Allied Customers: While

Delco-Remy was the corporate directed supplier of electrical components

to Chevrolet, Fisher Body, GM of Canada, and GMC for their trucks and

armored vehicles during World War Two, Delco-Remy also supplied a number

of non-GM customers during the war.

International Harvester, Marmon-Herrington,

and Kenworth:

This is an International H-542-9, 5-ton 4x2

tractor owned by the Navistar Corporation and stored at its Melrose

Park, IL plant. The military designation for the H-542-9 was the M425.

International built 4,640 in 1944 and 1945. International also built

6,678 H-542-15 with military designation M426. They were nearly

identical, except for larger tires and a heavier duty suspension on M426

which allowed it to pull larger loads. Author's photo added

12-1-2020.

Marmon-Herrington in Indianapolis, IN and

Kenworth in Seattle, WA also produced the M426.

|

Total M425 and M426 Tractors

built |

| |

M425 |

M426 |

|

International Harvester |

4,640 |

6,678 |

|

Marmon-Herrington |

|

3,200 |

|

Kenworth |

|

1,100 |

|

Totals |

4,640 |

10,978 |

| |

|

|

|

Grand Total |

15,618 |

Delco-Remy supplied the electrical equipment

for the 15,618 5-ton 4x2 tractors. The original 40-amp generator

was 1105864 which was later replaced by 1105871. Part

numbers for the remaining components are unknown.

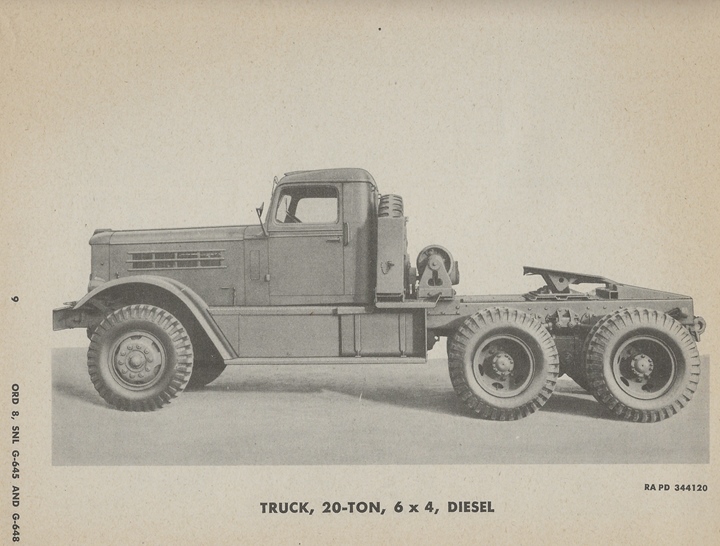

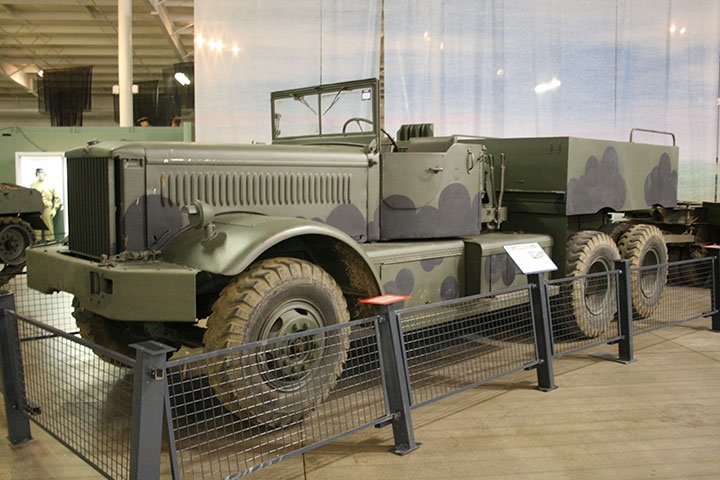

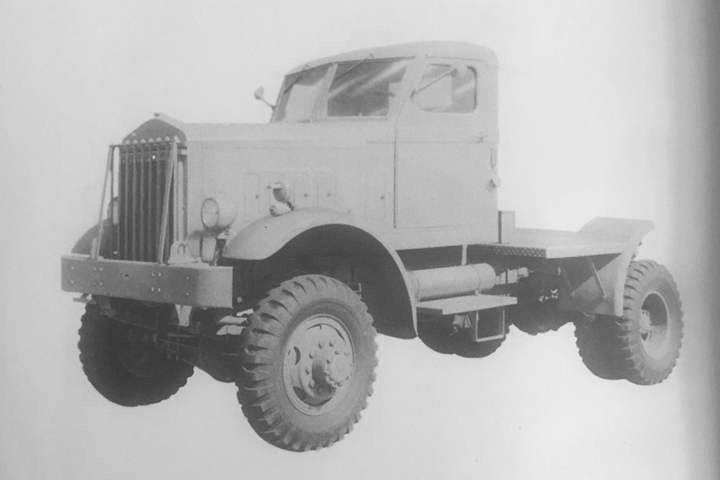

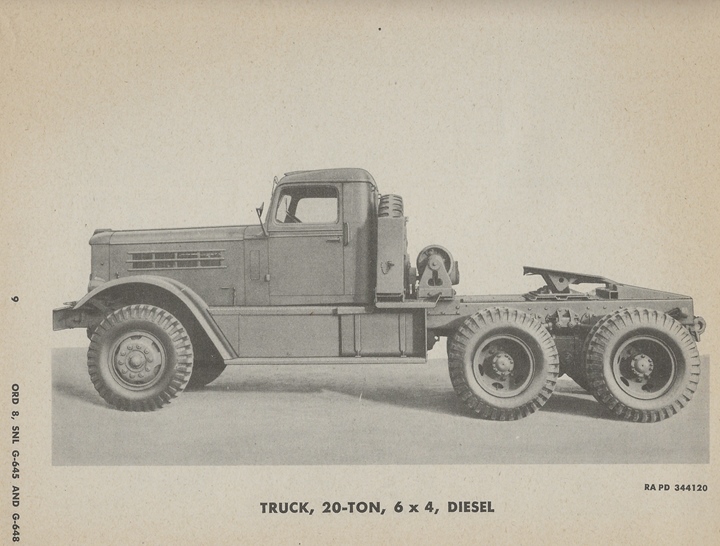

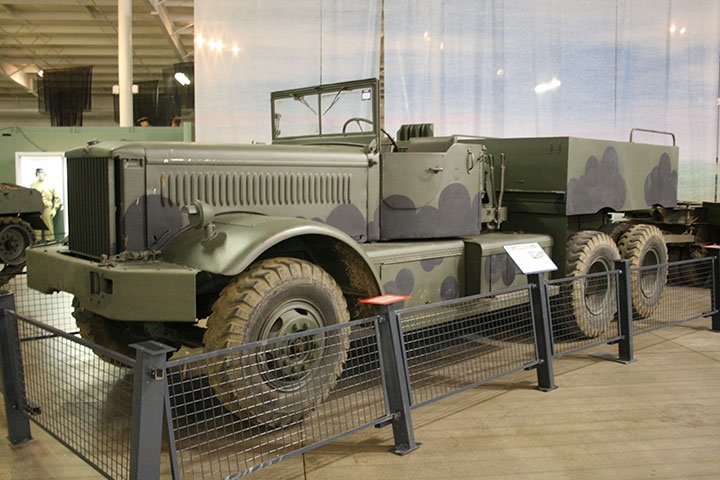

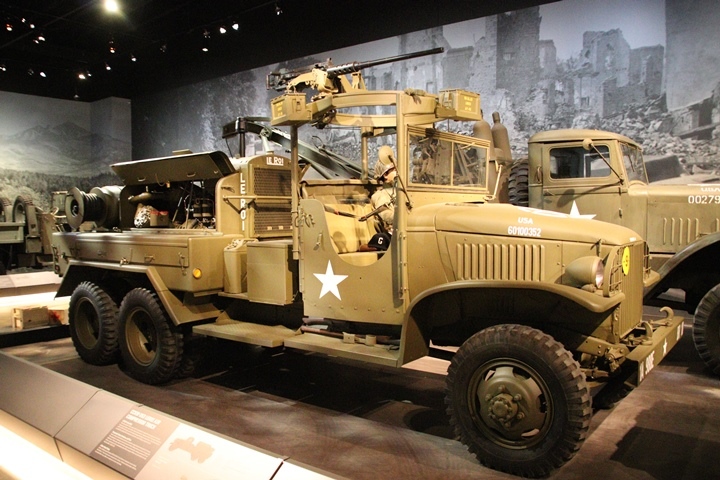

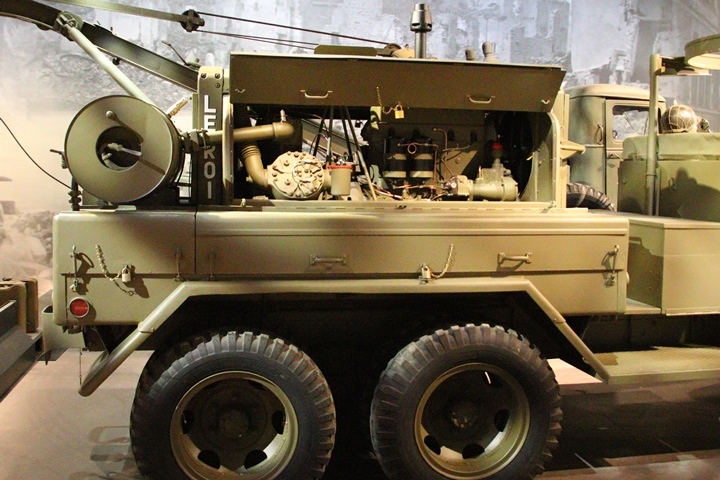

The Truck, 20-Ton, 6x4, Diesel was a Federal

Truck Company of Detroit, MI design, which was also built by The Reo

Motor Car Company in nearby Lansing, MI. The trucks were designed

and built to pull semi-trailers with heavy loads, including tanks.

The one shown above is a Federal-built unit because it has a winch.

Reo only built the non-winch version. Both types were powered by a

Cummins HB600 engine. Delco-Remy shipped the cranking motors and

DC generators to Cummins Engine Company in Columbus, IN. D-R also

shipped switches to Federal Truck in Detroit and the Reo Motor Car

Company in Lansing, MI.

|

Number of Federal and Reo 20-ton

6x4 Tractors |

|

Type |

Model |

1942 |

1943 |

1944 |

1945 |

Total |

| 20-ton 6x4

Tractor |

Federal 604 |

833 |

130 |

480 |

|

1,443 |

|

20-ton 6x4 Tractor |

Reo 28XS |

700 |

|

|

|

700 |

|

Total |

|

1,533 |

130 |

480 |

|

2,143 |

Delco-Remy supplied the sixteen OEM electrical

components for 2,143 20-Ton, 6x4 Diesel trucks form 1942 to 1944.

Delco-Remy OEM Parts for the Federal and Reo 20-Ton, 6x4

Trucks

Delco-Remy supplied 2,143 of each of these for these trucks.

The listing will below will show dozens of other components

to repair these items. |

|

Component |

D-R Part Number |

|

Generator, Assembly |

1106656 |

|

Regulator, Current, Assembly |

1183180 |

|

Regulator, Generator, Voltage and Current, Assembly |

1118476 |

|

Regulator, Voltage, Assembly |

185690 |

|

Relay, Cutout, for Generator, Assembly |

1831041 |

|

Motor, Cranking, 24 Volt |

000711 |

|

Relay, Instrument Control |

269-S |

|

Solenoid, Fuel Pump, Assembly |

1118061 |

|

Solenoid, Cranking Motor |

1118043 |

|

Switch, Blackout, Assembly |

1194513 |

|

Switch, Instrument Panel Light, Assembly |

1195602 |

|

Switch, Light Dimmer, Assembly |

1197014 |

|

Switch, Series Parallel |

407-J |

|

Switch, Solenoid, Shutoff, (Fuel Pump Solenoid) |

1196024 |

|

Circuit Breaker, Cut-Out, Thermal |

1185099 |

|

Relay, Horn |

1116775 |

For more information on this topic, go to:

Delco-Remy Electrical

Components for the Reo and Federal Truck, 20-Ton, 6x4

Studebaker and Reo:

Delco-Remy supplied head light dimmer

switches for 218,863 Studebaker US6 2-1/2-ton 6x6 and 6x4 trucks.

Originally, Delco-Remy furnished part number 1997008. This was

superseded by part number 1997014 which was water proof.

Delco-Remy supplied 22,204 1997014s to Reo for the US6 trucks it built.

Author's photo added 12-1-2020.

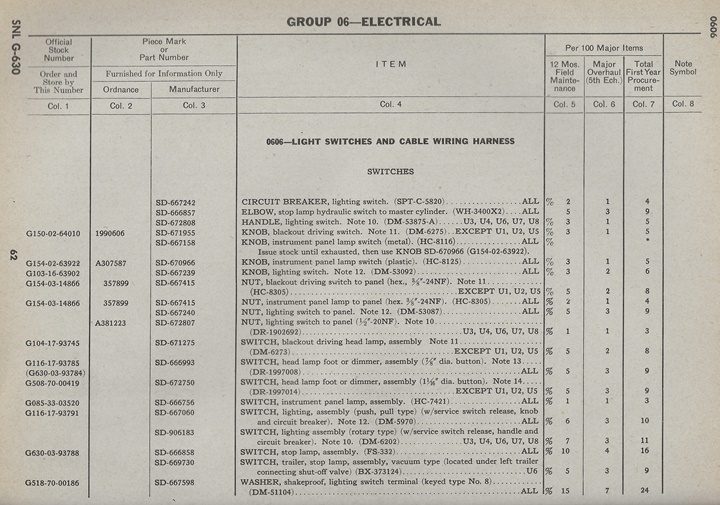

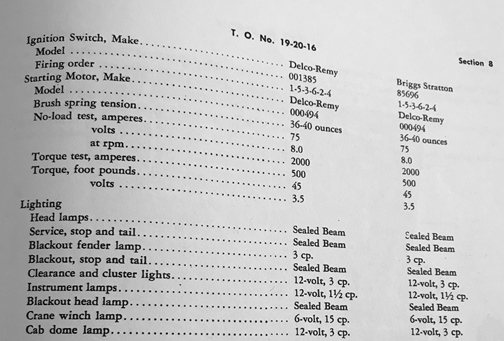

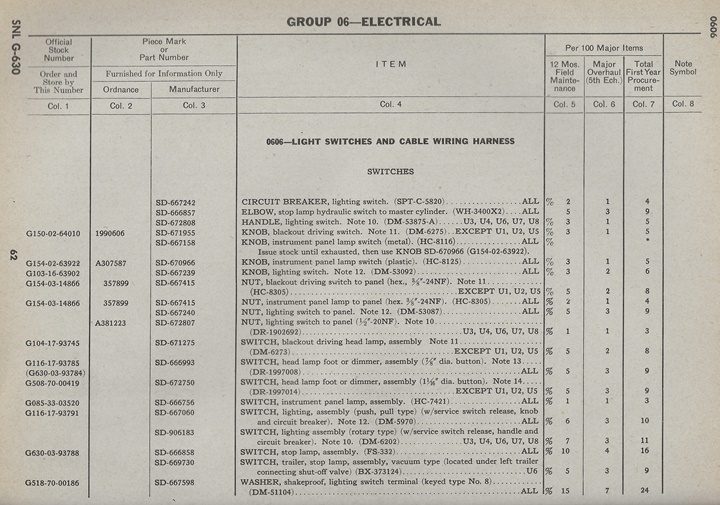

This page from the "Ordnance Supply Catalog,

Truck, 2-1/2-ton, 6x6 (Studebaker and Reo) and Truck, 2-1/2-ton, 6x4

(Studebaker)" shows Delco-Remy part numbers 1997008 and 1997014. It

also shows the Delco-Remy nut 1902692 to fasten the switches to the

floorboard of the trucks. These were the only parts Delco-Remy

supplied for this vehicle. Image added 12-1-2020.

Diamond T:

There were 5,871 Diamond T 12-ton 6x4

Tractor M20 tank transporter tractors built between 1941 and

1945. These were powered by a Hercules DFXE Diesel Engine with

Delco-Remy electrical components. These were the cranking motor

solenoid switch, DR-1118150; Cranking motor, DR-833; generator current

regulator, DR-1883180; generator voltage regulator, DR-1858690;

generator, DR-1106654. Author's photo added 3-10-2021.

Mack Trucks:

Mack Model NM 6-Ton 6x6 Trucks: These trucks came equipped

with Delco-Remy DC 25 ampere generator model number DR-1105866, voltage

regulator model number DR-5628, starting motor model number DR-1109104,

starting motor magnetic switch model number DR-1118008, distributor

model number DR-1110157, distributor vacuum control unit model number

DR-1116019, and ignition coil model number DR-1115149. Mack built

7,237 of these for the war effort.

This Mack NM-7 is on indoor display at the

National Museum of Military Vehicles in Dubois, WY. Author's photo

added 12-18-2024.

This Mack NM-6 is on outdoor display along

the Wind River at the National Museum of Military Vehicles.

Author's photo added 12-18-2024.

This NM-8D is part of the collection of the

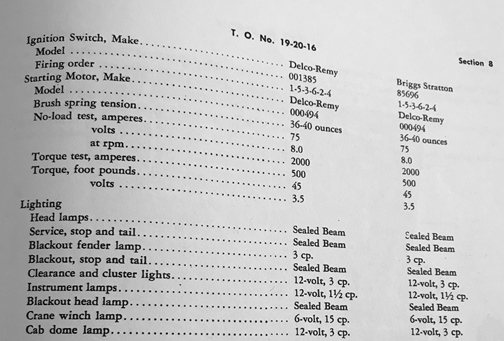

Mack Historical Truck Museum. Author's photo added 12-18-2024.

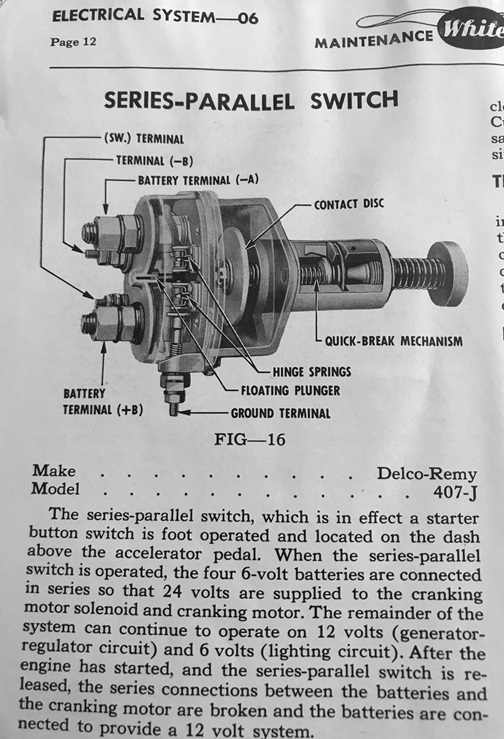

Mack Model NO 7-1/2-Ton 6x6 Trucks:

These trucks came equipped with Delco-Remy DC 25 ampere generator model

number DR-1105866 or DR-1105872, voltage regulator model number DR-5628,

starting motor model number DR-1109104, starting motor magnetic switch

model number DR-1118008, series-parallel switch model number DR-407-J

distributor model number DR-1110157, distributor vacuum control unit

model number DR-1116019, and ignition coil model number DR-1115149.

Mack built 2,147 of these for the war effort.

This meticulously restored Mack NO-7 is owned by John Gott. Image

courtesy of Jeff Lakaszcyck added 12-18-2024.

The Mack NO series of trucks were used by

the U.S. Army as prime movers for 155mm Long Tom artillery pieces during

World War Two. Image courtesy of Jeff Lakaszcyck added 12-18-2024.

Mack Model NR 10-Ton 6x4 Trucks:

The Mack NR 10-ton 6x4 cargo trucks were powered with a Mack-built

diesel engine. The generator and voltage regulators were supplied

by Delco-Remy, while the cranking motor was supplied by Leece-Neville.

The generator was DR-1106658, the current regulator DR-1883180,

and the voltage regulator DR-1858690. Mack built 15,528 of these

for the war effort.

A Mack NR 10-ton truck. Image added

12-18-2024.

Mack Model EHT 5-ton 4x2 Truck Tractor Conventional Cab and EHUT 5-ton

4x2 Truck Tractor COE Cab: These came equipped with the

following Delco-Remy components: DC generator model DR-1106586,

voltage regulator mole DR-1118212, starter Model DR-737-t, and

distributor Model DR-1110027. Mack built 140 Model EHTs and 180

EHUTs.

This is the EHT 4x2 tractor with

conventional cab. Image courtesy of Jeff Lakaszcyck added

12-18-2024.

Mack Model EH 5-Ton 4x2 Truck Conventional

Cab, and EHU

4x2 COE Cab:

These came equipped with a the following Delco-Remy components. DC

generator model DR-1106591, voltage regulator 1118244, starter model DR-737-t

starter switch model DR-405-c,

and distributor model DR-549-F. Mack built 2,960 EHs and 70 EHUs.

This is the EH 4x2 tractor with a

conventional cab. Image courtesy of Jeff Lakaszcyck added

12-18-2024.

6-ton 6x6 Trucks: Brockway Models

B666, C666, F666; Corbitt Model 50SD6, White Model 666: The Corbitt Company of Henderson, NC developed the

6-ton 6x6 truck used by the U.S. Army during World War Two. This

was its Model 50SD6. It was an excellent design but Corbitt did

not have the manufacturing capability to produce all the trucks that

were required for the war effort. Therefore, both the Brockway

Motor Company and the White Motor Company began building under license provide the number of

trucks needed. There were seven different types of 6-ton, 6x6

trucks built using the basic chassis. The total number of 6-ton

6x6 trucks built as shown in the table below was 13,064.

Delco-Remy therefore supplied 13,064 plus

spare parts of the following model numbers for these trucks.

DC Generator: 1904201

Voltage Regulator: 1883183

Current Regulator: 1883180

Cranking Motor: 494

Cranking Motor Switch: 1422

Distributor: 1110151, 1110178, 1110133

Ignition Coil: 1115149

Ignition Switch: 1997797

Light and Blackout Switch: 1902693

Foot Dimmer Switch: 1997014

Instrument Panel Light Switch: 7421

Magnetic Starting Switch: 1422

Thermostat Lighting Switch: 1994122

|

Brockway

Motor Company World War Two 6-Ton 6x6 Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Brockway Model |

Purchase Order Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector |

B-666 |

74-ORD-2709 |

|

|

384 |

271 |

|

|

655 |

| 6-ton 6x6 Chassis

w/w for the Daybrook M-II-A Bridge Erector |

B-666 |

74-ORD-2710 |

|

|

|

370 |

141 |

|

511 |

| Total

|

|

|

|

|

384 |

641 |

141 |

|

1,166 |

| |

|

|

|

|

|

|

|

|

|

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

74-ORD-3552 |

|

|

|

237 |

297 |

|

634 |

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

30115-ORD-312 |

|

|

|

|

312 |

318 |

630 |

| 6-ton 6x6 Chassis

w/w for Quickway Crane |

C-666 |

30115-ORD-1238 |

|

|

|

|

|

148 |

148 |

|

Total |

|

|

|

|

|

237 |

609 |

466 |

1,312 |

| |

|

|

|

|

|

|

|

|

|

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

740-ORD-2710 |

|

|

|

|

174 |

26 |

200 |

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

30115-ORD-312 |

|

|

|

|

|

36 |

36 |

| 6-ton 6x6

Chassis, Fire |

B-666, F-666 |

30115-ORD-1919 |

|

|

|

|

|

34 |

34 |

| Total

|

|

|

|

|

|

|

174 |

96 |

270 |

| Brockway Grand

Total |

|

|

|

|

|

|

|

|

2,748 |

| |

|

|

|

|

|

|

|

|

|

|

Corbitt Company

World War Two 6-Ton 6x6 Trucks

Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945."

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

Corbitt Model |

Contract Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

398-QM-8279 |

|

203 |

|

|

|

|

203 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

398-QM-9088 |

|

300 |

|

|

|

|

300 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

398-QM-10941 |

|

|

100 |

|

|

|

100 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

398-QM-11606 |

|

297 |

303 |

|

|

|

600 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

398-QM-12065 |

|

|

|

396 |

4 |

|

400 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

670-ORD-5023

670-ORD-5023B |

|

|

|

232 |

|

|

232 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

670-ORD-5023

670-ORD-5023B |

|

|

|

|

416 |

|

416 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

670-ORD-5023

670-ORD-5023B |

|

|

|

|

195 |

456 |

651 |

| Truck, 6-Ton,

6x6, Prime Mover w/w |

50SD6 |

36034-ORD-2616 |

|

|

|

|

|

309 |

309 |

| Corbitt Grand

Total |

|

|

|

|

|

|

|

|

3,211 |

| |

|

|

|

|

|

|

|

|

|

|

White Motor Company

World War Two

6-Ton 6x6

Trucks Accepted by Detroit Ordnance, US Army

The information below comes from "Summary Report of

Acceptances, Tank-Automotive Material, 1940-1945"

Published by Army Services Forces, Office, Chief of

Ordnance-Detroit, Production Division, Requirements and

Progress Branch

January 21, 1946. |

|

Type |

White Model |

Contract Number |

1940 |

1941 |

1942 |

1943 |

1944 |

1945 |

Total |

| 6-ton 6x6 Chassis

w/w for Bridge Erector |

666CE |

|

|

|

|

|

823 |

329 |

1,152 |

| 6-ton 6x6 Chassis

Van |

666 |

|

|

|

1,062 |

808 |

|

|

1,870 |

| 6-ton

6x6 Prime Mover w/w |

666 |

|

|

|

726 |

795 |

669 |

1,756 |

3,946 |

| 6-ton

6x6 Tank Gas 2000 Gal |

666 |

|

|

|

|

25 |

|

|

25 |

| 6-ton

6x6 Tractor |

666 |

|

|

|

|

|

|

112 |

112 |

| White Grand

Total |

|

|

|

|

|

|

|

|

7,105 |

| |

|

|

|

|

|

|

|

|

|

|

Grand Total of 6-Ton 6x6 Trucks |

|

|

|

|

|

|

|

|

13,064 |

This

Corbitt 50SD6 is part of the collection of the World War II

American Experience Museum in Gettysburg, PA. Author's photo added

12-18-2024.

Author's photo added 12-18-2024.

This White Motor Company Model 666 prime

mover is on display at the Army Transportation Museum at Fort Eustis,

VA. This is a later model as it has a soft top cab. Author's

photo added 12-18-2024.

The White Model 666 is part of the large

collection of World War Two trucks at the National Museum of Military

Vehicles in Dubois, WY. This is an early model with a hard top

cab. Author's photo added 12-18-2024.

Author's photo added 12-18-2024.

This

Brockway Model B-666 Bridge Erector Truck is also part of the truck

collection on display at the National Museum of Military Vehicles.

Author's photo added 12-18-2024.

Author's photo added 12-18-2024.

This is a Brockway model C-666 chassis with a Quick-Way crane. John Gott photo via Jeff Lakaszcyck

photo added 12-18-2024.

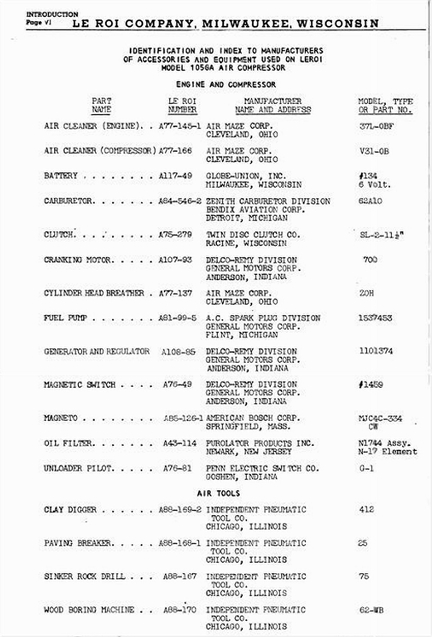

Le Roi Company's Air Compressors: The

Le Roi Company produced over 10,000 air compressor units that were

mounted on 819 GMC AFK-352 1-1/2-ton 4x4 trucks and at least 9,609CCKW

2-1/2-ton 6x6 trucks. Delco-Remy not only supplied the electrical

components for the GMC trucks but for the Le Roi-built gasoline engine

that drove the air compressor.

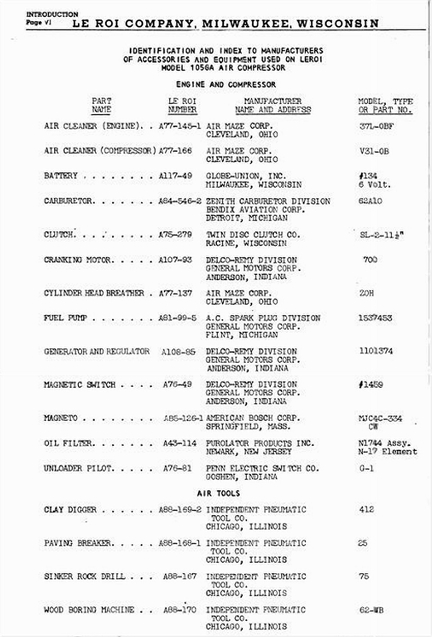

This part's list is from TM 5-5060, Le

Roi Motorized Air Compressor, Model 105GA Technical Manual.

It includes Independent Pneumatic "Thor" Air Tools, 1942.

It shows the Delco-Remy part numbers. The cranking motor is DR

model number 700, the DC generator and regulator is DR model number

1101374, and the magnetic switch is DR model number 1459. Image

added 12-18-2024.

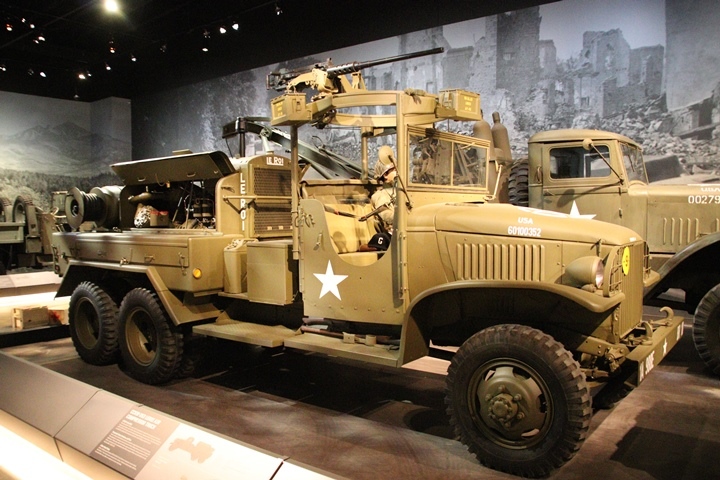

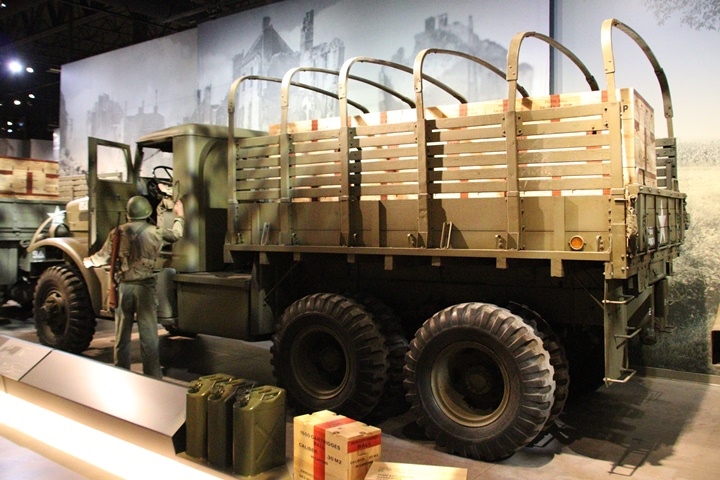

This Le Roi compressor truck is on display

at the National Museum of Military Vehicles in Dubois, WY.

Author's photo added 12-18-2024.

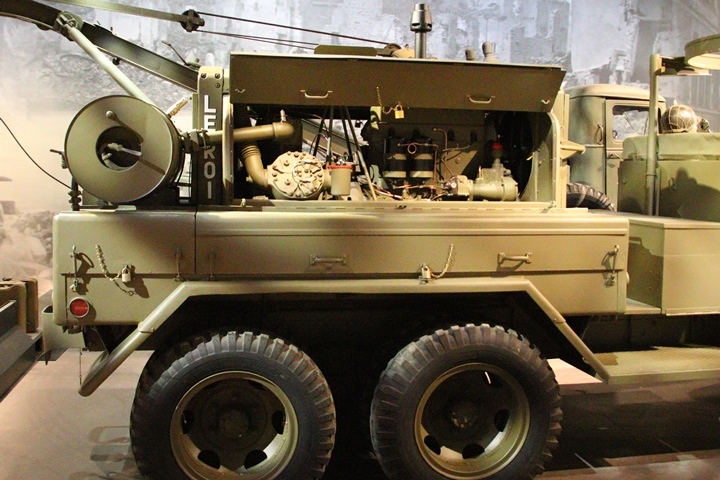

This shows the passenger side of the air

compressor and gasoline engine. Author's photo added 12-18-2024.

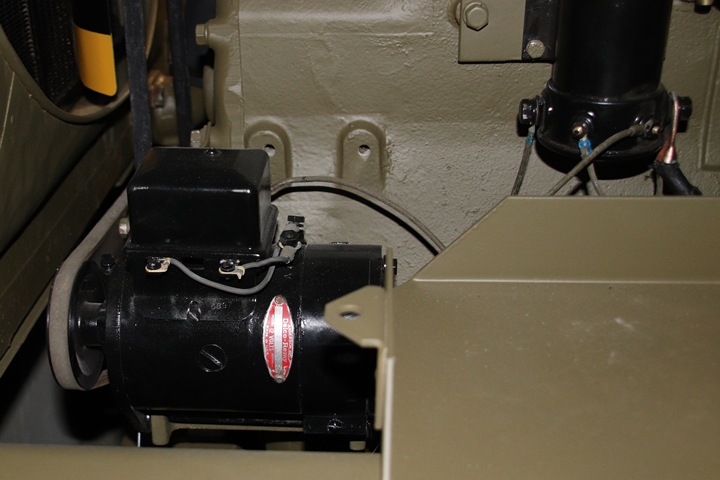

The Delco-Remy components are on the

driver's side of the truck, as shown in this and the following photos.

Author's photo added 12-18-2024.

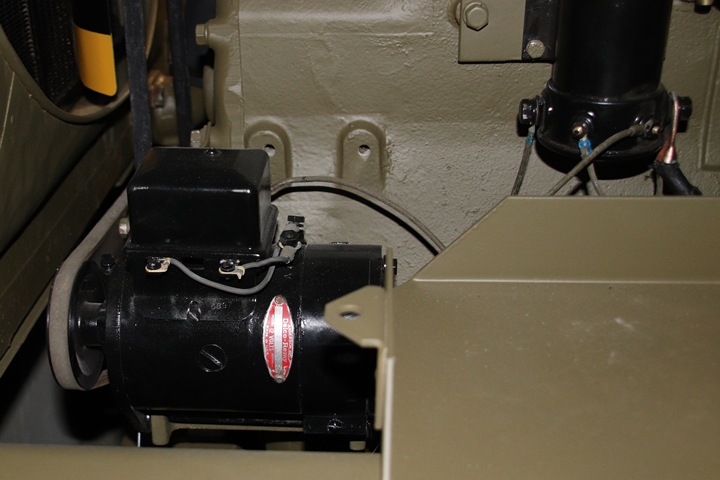

The magnetic switch is located in the left

of the photo and the cranking motor is in the right side of the image.

Author's photo added 12-18-2024.

The DC generator with a regulator mounted on

it is in the lower left of this photo. The bottom of the magnetic

switch can be seen in the upper right. This photo shows the large

gauge electrical cable that supplies the large current load to the cranking

motor. Author's photo added 12-18-2024.

Sterling Motor Truck Company:

Sterling was a small heavy-duty truck manufacturer located in Milwaukee,

WI.

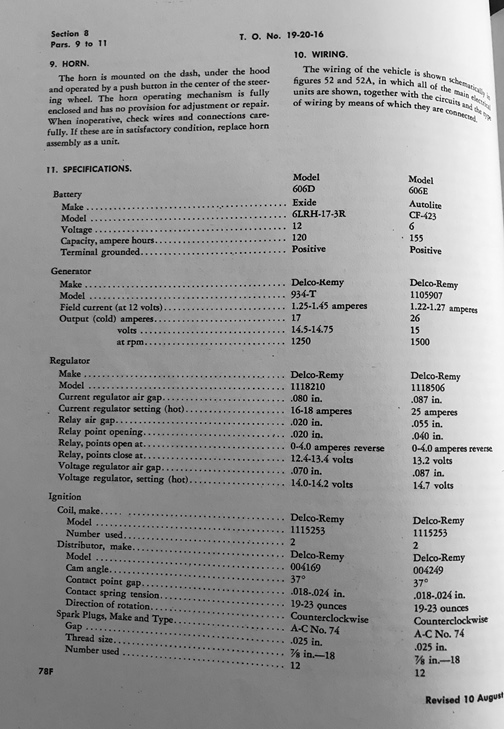

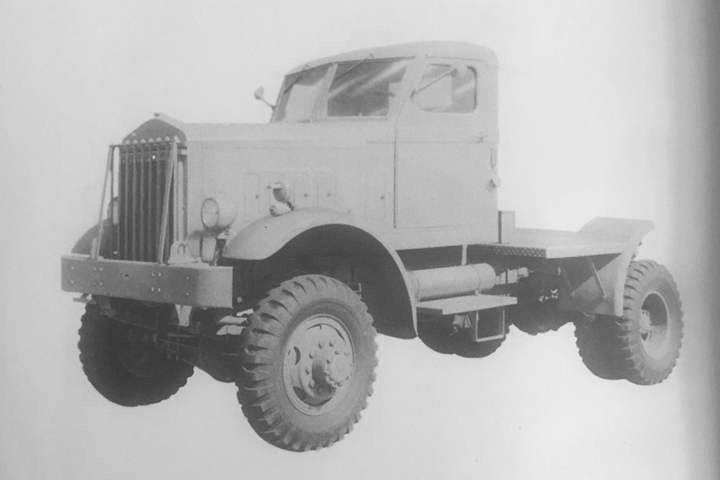

The Sterling Motor Truck Company of

Milwaukee, WI built 50 DD115 4x4 tractors for the U.S. Navy in World War

Two. The DD115 was powered by a Waukesha 6SRKR six cylinder engine

with a Delco-Remy electrical system. The part numbers were:

cranking motor - 412, DC generator - 934D, voltage regulator - 1118210,

distributor - 640C, ignition coil - 1115079. Image courtesy of

Warren Richardson added 12-24-2020.

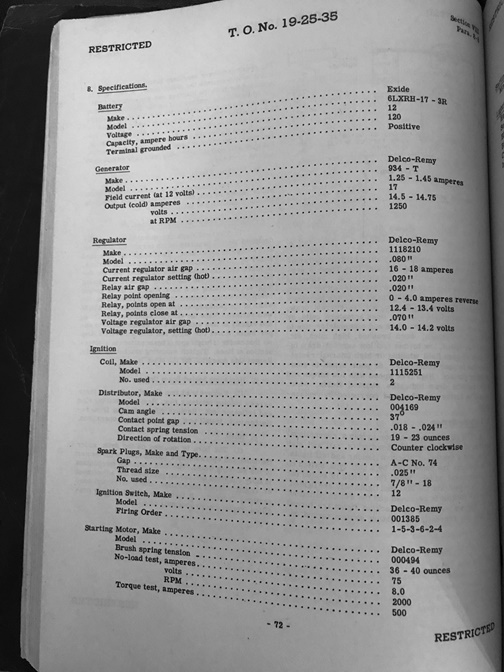

Federal Type Model 605 F-1 Aviation Fuel Tractors:

Two hundred of these were built for the USAAF.

Image courtesy of Jeff Lakaszcyck added

12-24-2020.

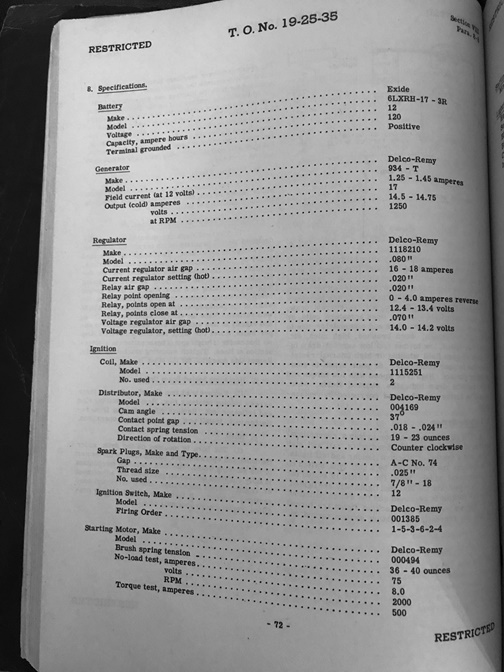

While the engine ignition system was

Delco-Remy, Exide manufactured the twelve volt battery. Other

heavy duty trucks had Willard batteries. Delco-Remy batteries did

not have much or really any penetration into the heavy duty truck market during

World War Two. It may have been running at capacity to supply all

of the Chevrolet and GMC trucks during the war. The Muncie battery

plant was also producing aircraft batteries and supercharger blowers for

the war effort. Image courtesy of Jeff Lakaszcyck added 12-24-2020.

The Delco-Remy part numbers were: cranking

motor - 494, DC generator - 934T, voltage regulator - 1118210,

distributor - 4169, ignition coil - 1115251. The Federal F1 fuel

truck used two ignition coils.

The magnetic starting switch was model

number 1422. Image courtesy of Jeff Lakaszcyck added 12-24-2020..

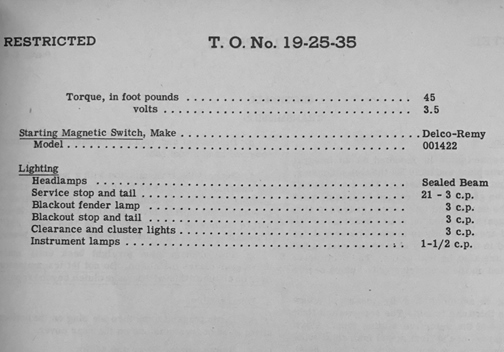

Federal Type C-2 7-1/2-ton 6x6 606 Aircraft Wrecker: The C-2

was powered by a Hercules Model HXD six cylinder 855 cu. in. engine,

which enabled the truck to pull 12.5 tons when hooked up to a trailer.

The truck could perform several different tasks. However, its primary

job was to pick up disabled aircraft and place them on a trailer to take

to the repair facilities. It was also used extensively for

aircraft engine changes. Every AAF Air Base had at least one C-2.

While one C-2 could lift most aircraft on its own, it took two to lift a

B-17, so the bases with heavy bombers or transports like the C-54 would

have had two.

Federal built 2,500 Federal 606 aircraft

wreckers for the USAAF. The USAAF designated it as the C-2.

Photo courtesy of Taigh Ramey and

www.twinbeech.com added

12-24-2020.

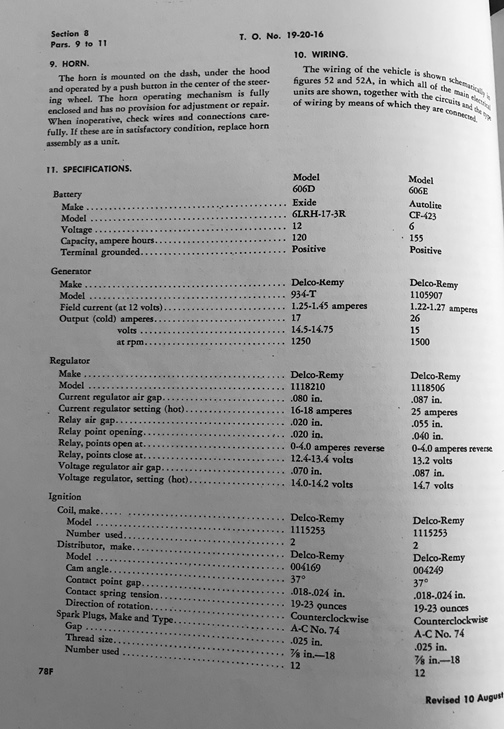

The Federal 606 had two different electrical systems for it as shown

depending on whether it was a 606D or 606E. The two different

models also had non-Delco-Remy batteries. Image courtesy of Jeff Lakaszcyck

added 12-24-2020.

Federal 606D Delco-Remy part numbers were:

cranking motor - 494, DC generator - 934T, voltage regulator - 1118210,

distributor - 4169, ignition coil - 1115253, ignition switch - 1385.

Federal 606E Delco-Remy part numbers were:

cranking motor - 494, DC generator - 1105907, voltage regulator -

1118506, distributor - 4249, ignition coil - 1115253, ignition switch -

This was a Briggs and Stratton switch.

This vehicle also used two ignition coils.

Image courtesy of Jeff Lakaszcyck added

12-24-2020.

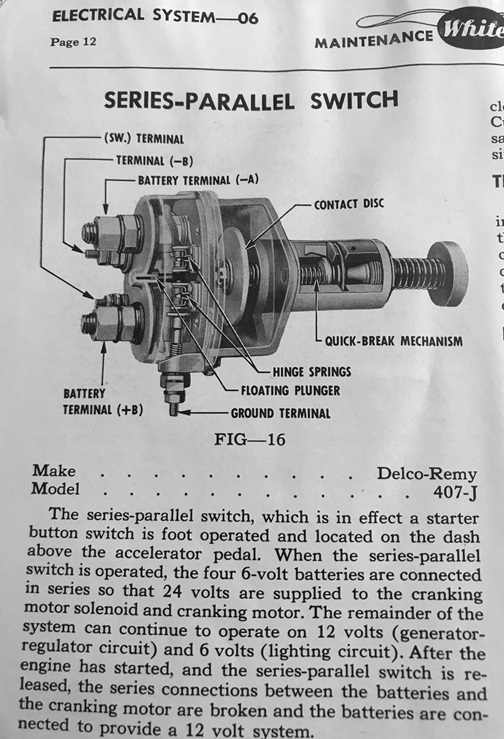

White 1064 10-ton 6x4 Truck:

White built 2,500 Model 1064 with Cummins

HB600 diesel engines. These vehicles had a Delco-Remy 12 volt

positive ground electrical system. The Delco-Remy part numbers

were: generator-1106656, voltage regulator-1118476, cranking

motor-711 24 volt. Photo added 12-24-2020.

This photo explains how the Delco-Remy

series-parallel switch, part number 407-J worked to provide 24 volts at

start for the normal 12 volt system. Image courtesy of Jeff Lakaszcyck

added 12-24-2020.

Cook Brothers and Corbitt Prototypes:

This is a T20 8-ton 8x8 prototype cargo truck

built in 1945 by the Cook Brothers in Los Angeles, CA. It had a 12

volt Delco-Remy electrical system in it. The generator was a 55

amp unit. The T20 never went into production. Author's photo

added 12-1-2020.

This is another prototype 8-ton 8x8 cargo

truck designated T20E and built by the Corbitt Company of Henderson, NC.

This is one of three that were built at the end of World War Two.

It had

12 volt Delco-Remy electrical systems. The generators were 55

amp units. The T20E never went into production. Author's

photo added 12-1-2020.

Low-Speed Tractors: These are

construction-type crawler tractors that were not intended for the

cross-country pulling of heavy artillery pieces, although they were used

for that function during the war along with traditional construction

work.

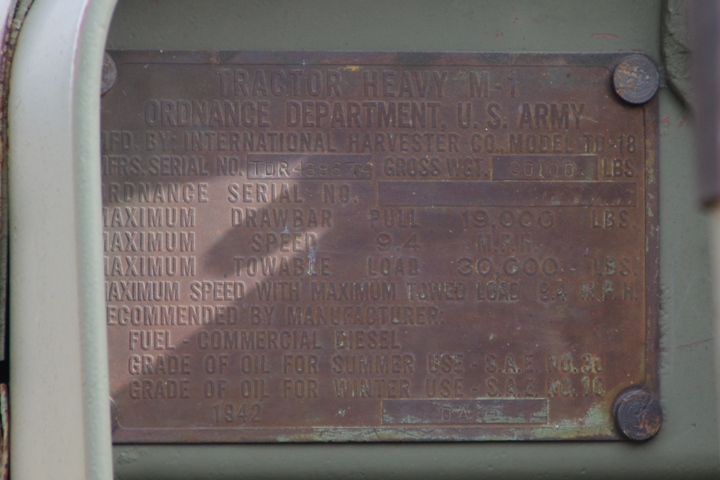

This is a 1942 Allis-Chalmers TD-18 tractor

built for the U.S. Army Corps of Engineers. It was photographed by

the author at the 2020 Antique Gas Engine and Tractor Show in Portland,

IN. Note that there are ignition wires on the engine and two

exhaust stacks. Photo added 9-2-2020.

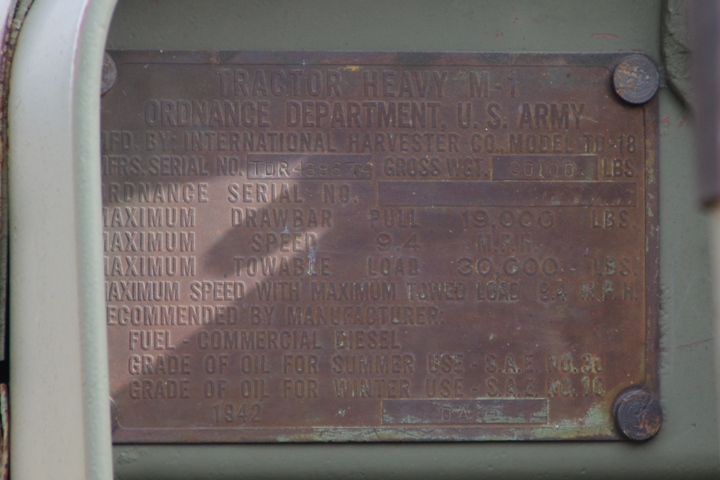

The U.S. Army nomenclature identified this

as a Tractor, Heavy M-1. Allis-Chalmers built 315 TD-18s

in 1942 and a total of 747 units during World War Two for the U.S. Army.

Delco-Remy supplied the electrical components for these 747 TD-18s.

Author's photo added 9-2-2020.

Author's photo added 9-2-2020.

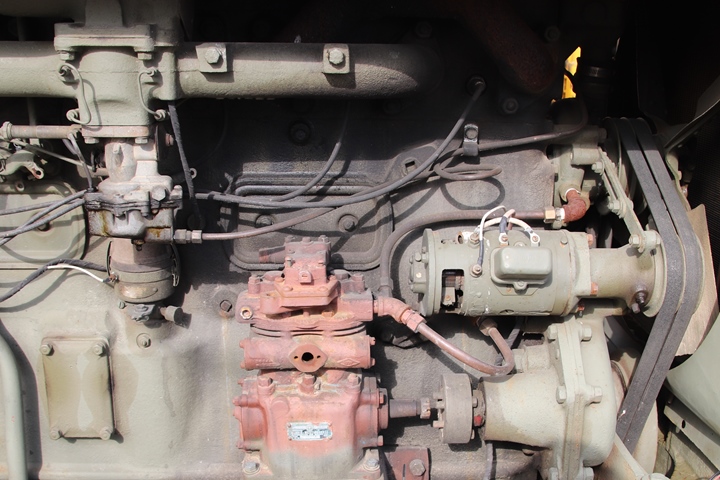

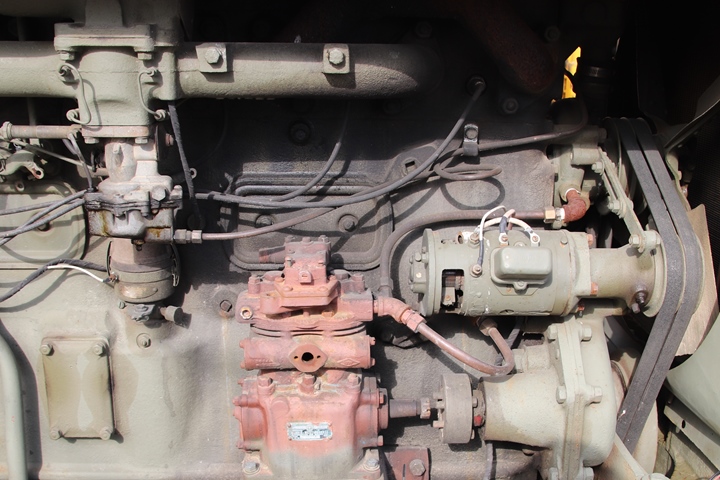

This side of the engine shows it to be

a six cylinder diesel engine. Note there is a gasoline container

on the track and a bird's nest on top of the engine. Author's

photo added 9-2-2020.

I had never seen anything like this

before. Further research found that the six cylinder gas engine

was used to start the engine before the diesel was turned on.

Author's photo added 9-2-2020.

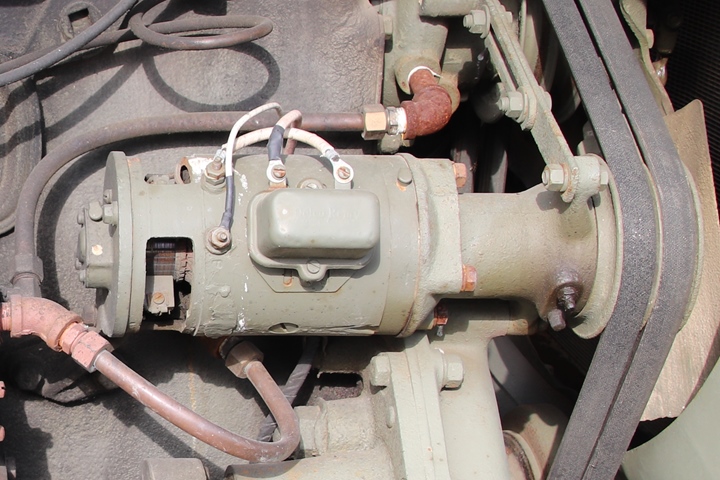

Further examination found that

Delco-Remy built the

distributor, DC generator, and voltage regulator. Part of the distributor is hidden behind the

carburetor. While the starter could not be seen, it is assumed to

be a Delco-Remy unit also. Author's photo added 9-2-2020.

Author's photo added 12-1-2020.

This is part number xxx0152 which is most

likely 1110152. It was a clockwise rotation distributor. The

date code shows it was built on June 21, 1942. Author's photo added

12-1-2020.

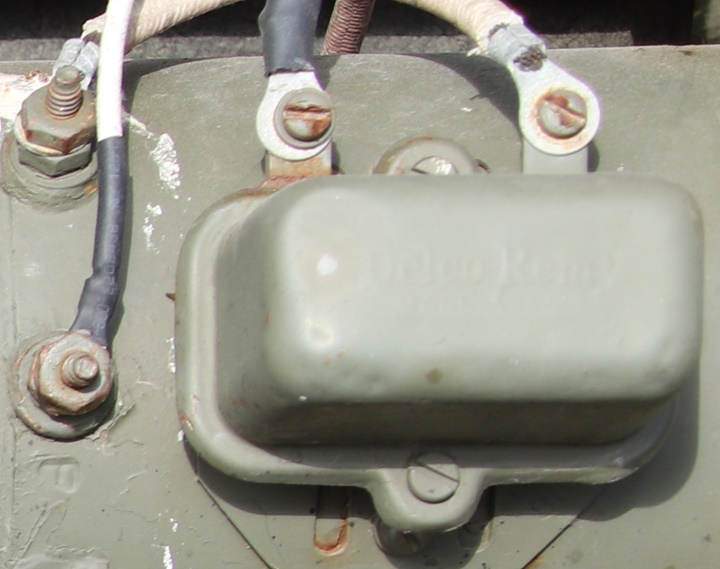

The DC generator has the voltage

regulator mounted directly to it. Author's photo added 9-2-2020.

The Delco-Remy name is stamped into

the regulator. Author's photo added 9-2-2020.

Author's photo added 9-2-2020.

High-Speed Tractors: These

tractors were specifically designed to pull heavy artillery

and were faster than the low-speed tractors.

The Allis-Chalmers M4 high speed tractor was powered by a Waukesha 145GZ

engine which had a Delco-Remy 644 heavy duty rear reduction cranking

motor. Author's photo added 5-10-2020.

Author's photo added 5-10-2020.

This is one of two surviving Allis-Chalmers

M6 high speed tractors of the 1,235 built during World War Two.

Like the smaller M4, it was powered by two Waukesha 145GZ engines

with a Delco-Remy electrical system. This is on display at the Overloons Military Museum in the Netherlands. Photo added

12-1-2020.

The other surviving M6 high speed tractor is

awaiting restoration at the Indiana Military Museum in Vincennes, IN.

It is 250 miles from where it was built in LaPorte, IN.

Author's photo added 12-1-2020.

This M2 high speed tractor is on display at the National Museum of the

Air Force in Dayton, OH. It was built by the Cleveland Tractor

Company and was called a "Cletrac." It was used by the Army Air

Force to move aircraft around at its bases. The M2 had Delco-Remy

a 6 volt DC generator model number 993, voltage regulator model number

5634, and cranking motor model number 1108408. The M2 had a

Delco-Remy distributor. 6,320 M2s were

built by Cleveland Tractor and another 2,190 were built by John Deere. Author's photo

added 12-1-2020.

These U.S. Army mechanics finished a two week

training course on Delco-Remy products during September 1942. Here

they can be seen working on the D-R contact regulators.

|