|

Delco-Remy in WWII

Delco-Remy WWII Marine

Equipment

Delco-Remy WWII Tank Products

Delco-Remy WWII Vehicle Products

Delco-Remy and LST-393

Delco-Remy WWII Kings Mills Plant

Delco-Remy WWII Antioch Foundry

Delco-Remy WWII

Stationary Engine Products

Delco-Remy WWII

Electrical Components for the Reo and Federal Truck, 20-Ton, 6x4

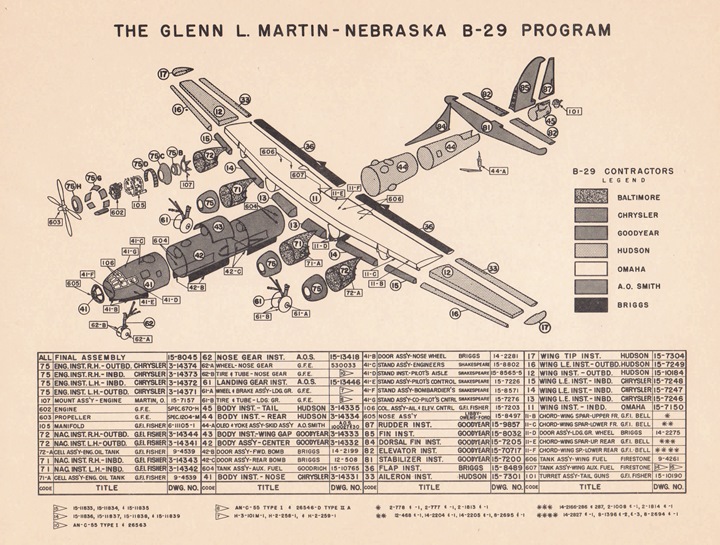

Delco-Remy Training Manuals for Aircraft Components The B-29 Project: Delco-Remy was one of seventeen GM Divisions that built components for the B-29. It was the most expensive project of WWII, being even more expensive than the Manhattan Project. No mention of the B-29 is made in the 1944 Delco-Remy booklet "Our War Job". There are two reasons for this. First, production on the B-29 did not start until mid-1944, and contracts and tooling were still being made when the booklet was published. Second, the B-29 project was considered "Top Secret." Delco-Remy would have only been able to state it was working on the project, but not what it was making for it. As diverse of an aircraft related product line produced by DR during WWII, the Division could have supplied any number of components for the B-29.

Starting at the front of the fuselage and working towards the rear of the aircraft, the glass nose section was built by Libby-Owens-Ford, an automotive glass company. The fuselage nose section was built by Chrysler's Plymouth Division in Detroit. Goodyear in Akron, OH built the two bomb bay fuselage sections. Briggs, an independent auto body manufacturer in Detroit, provided the bomb bay doors. The three rear fuselage sections behind the wings were also built in the city of Detroit by the Hudson Motor Car Company, which combined with Nash in 1954 to become American Motors. The entire tail section and the elevators with control surfaces were made by Goodyear, and the tail gunner's position was manufactured by the Fisher Body Division of GM at Cleveland, OH. Martin Omaha provided the center section of the wing. Chrysler provided the inboard leading edges. Hudson built the outer wing sections, outer leading edges, ailerons, and wing tips. Briggs provided the flaps. All four engine nacelles and engine oil tanks came from the Fisher Body Division of GM along with the exhaust manifolds. Omaha built the engine mounts; Dodge supplied the engines and Chrysler the engine cowlings. Firestone provided the main and auxiliary wing fuel tanks and BF Goodrich the fuselage auxiliary fuel tank. While Boeing designed the aircraft, there are no major fuselage, wing nor rear tail section components provided by that company. With the exception of the Martin wing center section, the rest of the wing was supplied by the American automobile industry. Inside the B-29 airframe and wing structural components listed above, there were tens of thousands of parts and components. The engine nacelles produced by the Fisher Body Division of GM had over 3,000 parts in them. Each nose fuselage section built by Chrysler had 5,000 parts in it. Many of the parts for many of the major components would have been supplied by AC Sparkplug, Allison, Brown-Lipe-Chapin, Buick, Chevrolet, Delco Appliance, Delco Products, Delco Radio, Delco-Remy, Fisher Body, Frigidaire, Harrison Radiator, Hyatt Bearings, Moraine Products, New Departure, Packard Electric, and Rochester Products Divisions of GM as identified in the 1944 GM Annual Report. Of significance is that the Martin Plant in Omaha, NE produced the Silverplate B-29 Nuclear Bombers.

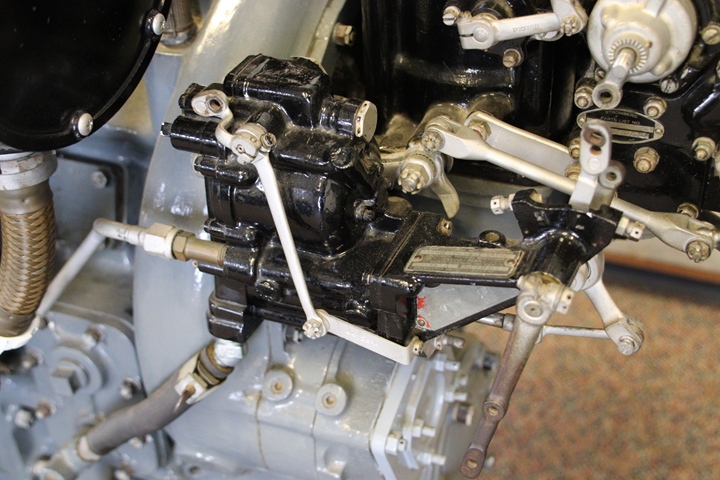

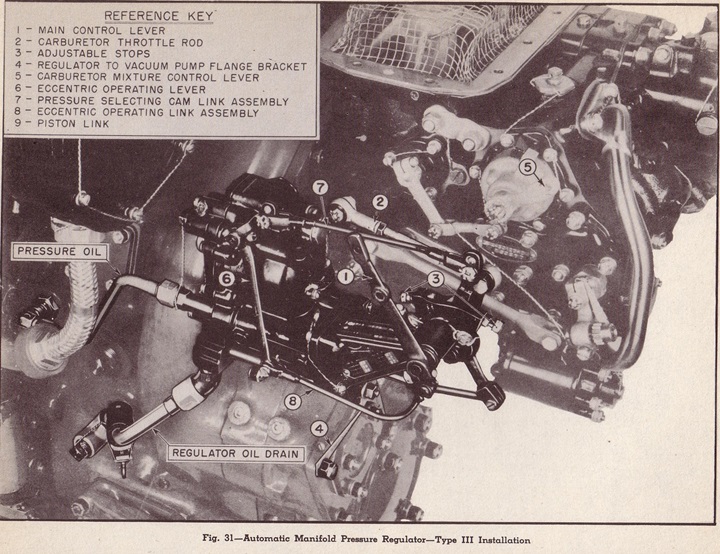

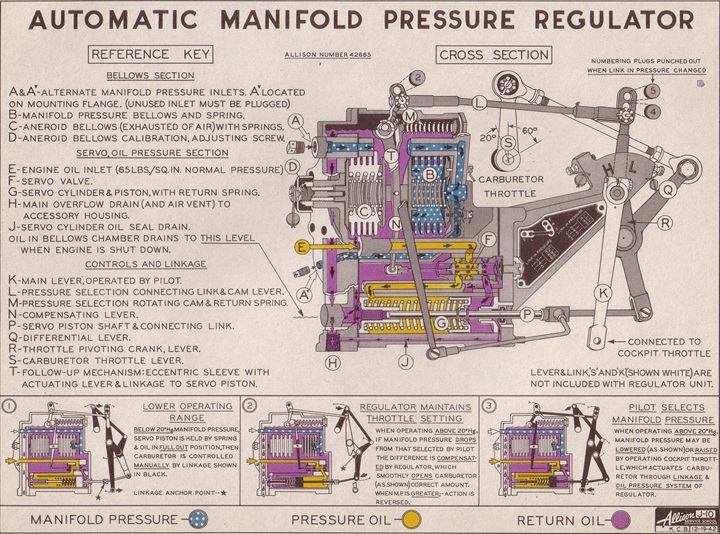

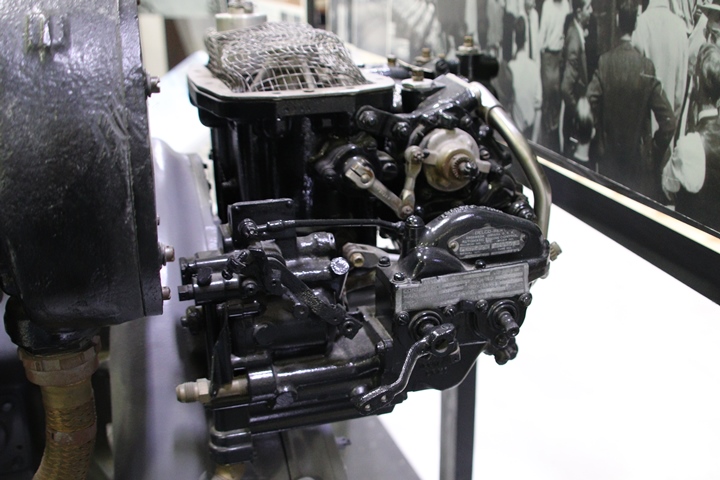

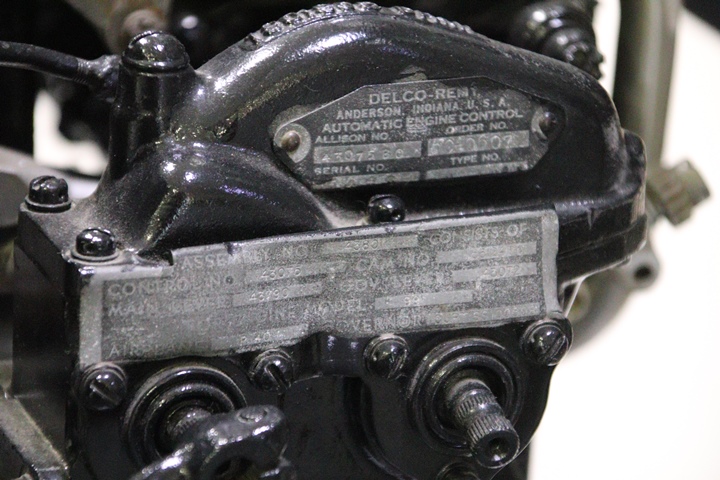

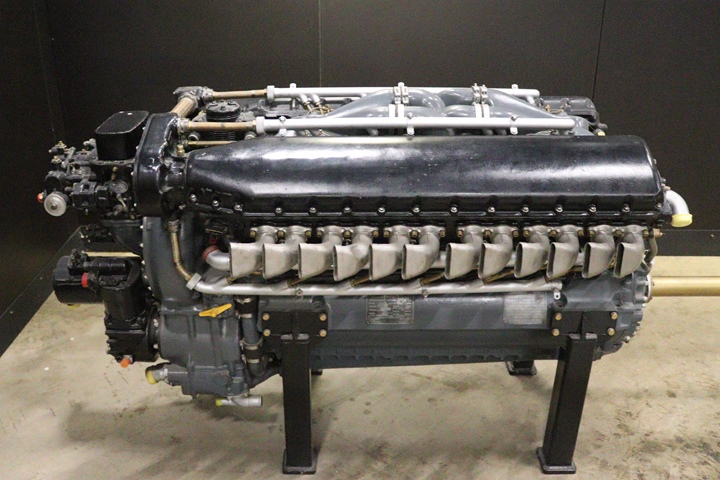

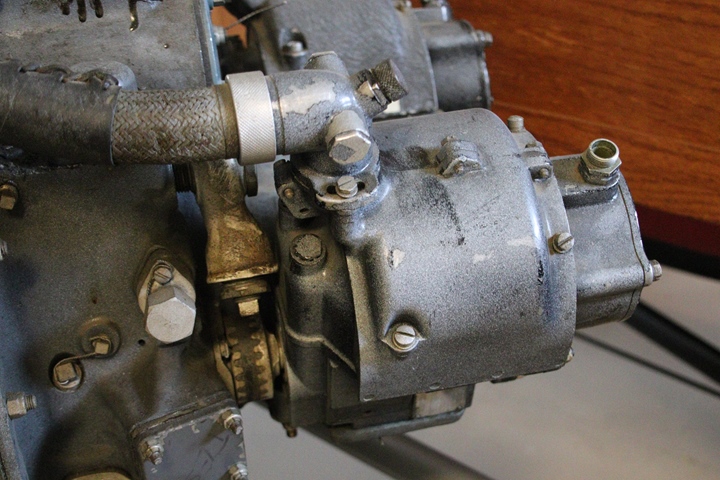

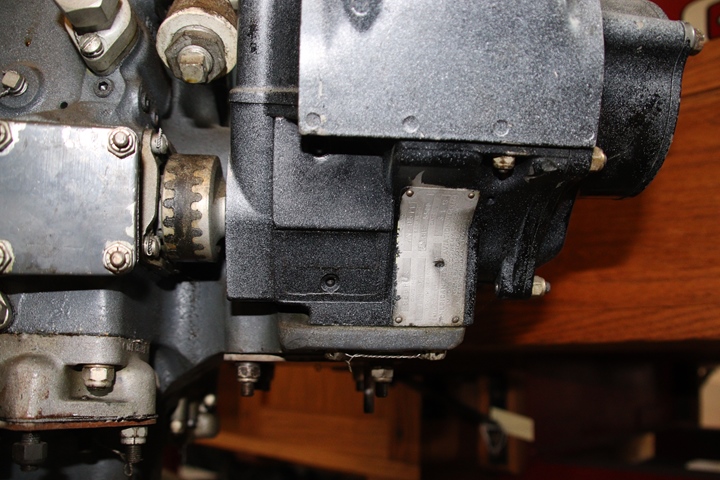

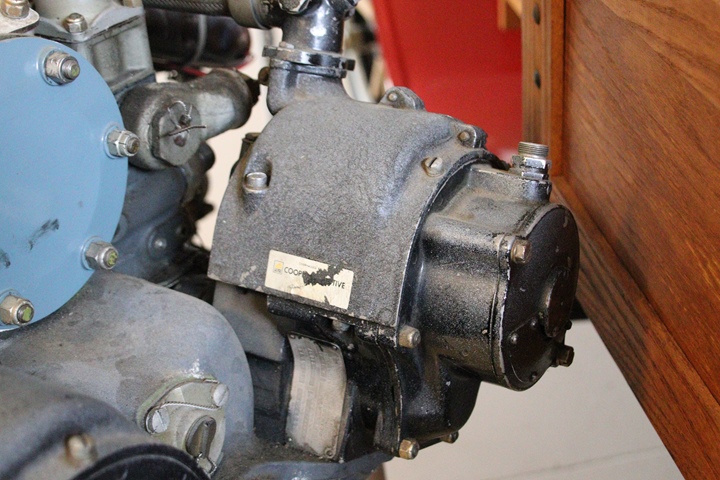

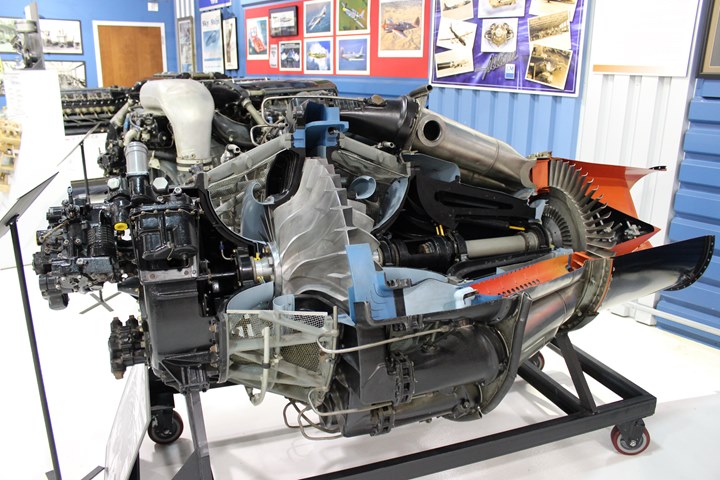

Army Air Forces and Navy Aircraft utilizing Delco-Remy Electrical Equipment in World War Two: Any of the described aircraft equipment could be on any of the aircraft listed below. It could have been one part or any number on the aircraft. The World War Two military aircraft with Delco-Remy components included but was not limited to: C-47, P-51, B-26, B-24, B-26, B-17, B-29, P-39, P-63, SBD, A-20, P-38, C-46, P-47, PV-1 Automatic Pressure Regulator for Allison V-1710 V-12 Aircraft Engine: This device maintains, within desirable limits, a selected manifold pressure from sea level up to the critical altitude of the supercharger. The selected sea level manifold pressure is maintained up to the critical altitude without any throttle adjustment. A drop of 1.5 Hg a the critical altitude is built into the regulator to keep the engine from producing excessive power during a climb when the manifold pressure is kept constant. This automatic pressure regulator was build in Plant Six and is on display at the Air Zoo Aviation Museum in Portage, MI. The Allison V-1710 engine it is attached to is located in the museum annex building. The regulator is serial number 15181 and is an AAF Type A2 regulator.

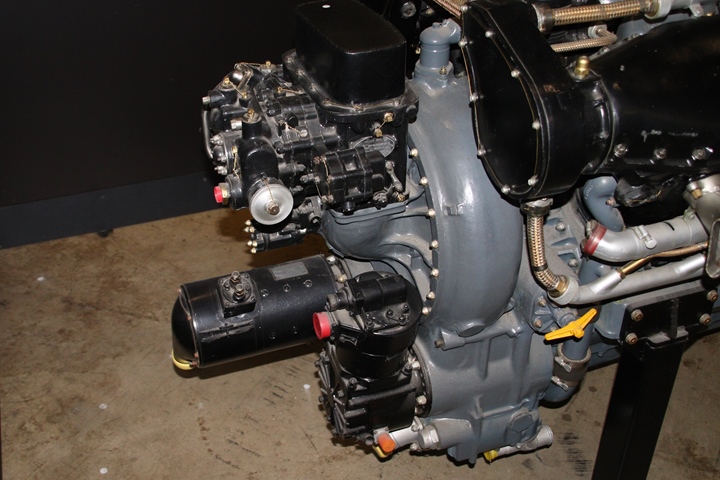

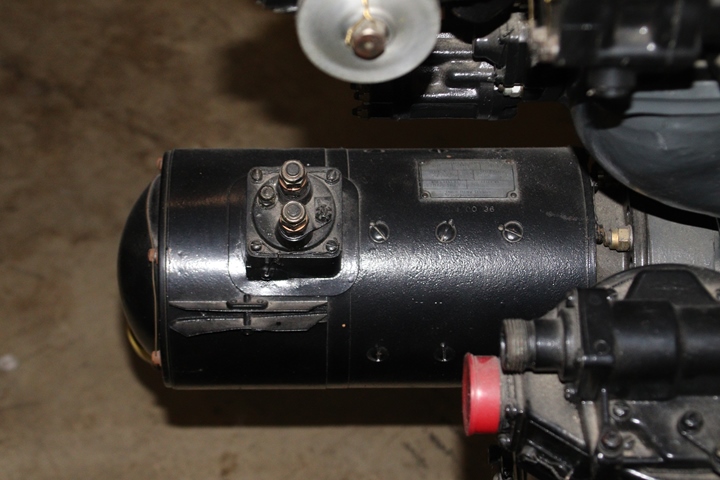

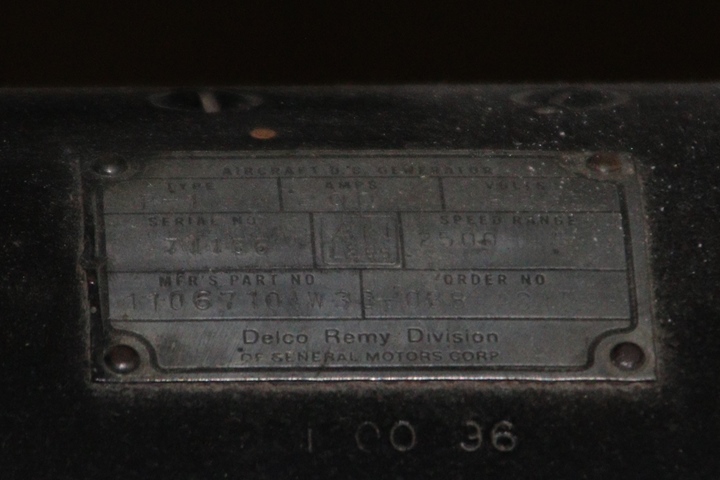

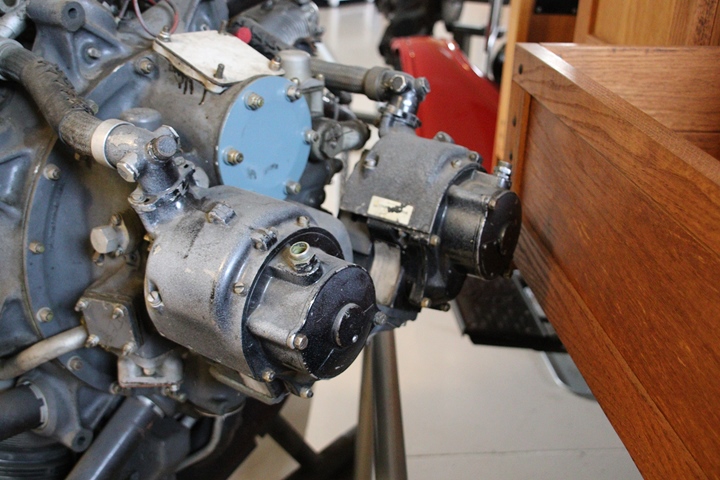

Aircraft DC Generator: Sometimes Delco-Remy World War Two products are hiding in plain sight. Many times I have stopped and looked and photographed the Allison V-1710-85 engine display near the P-39Q at the National Museum of the Air Force. On my visit of 9-9-2020 I decided to photograph the accessory section of the engine, and discovered it had a Delco-Remy DC aircraft generator. In the past, I had been more interested in the engine itself and possible D-R castings on it, and not the accessories.

Sperry Auto Pilot: Delco-Remy supplied solenoids for aircraft autopilots during WWII.

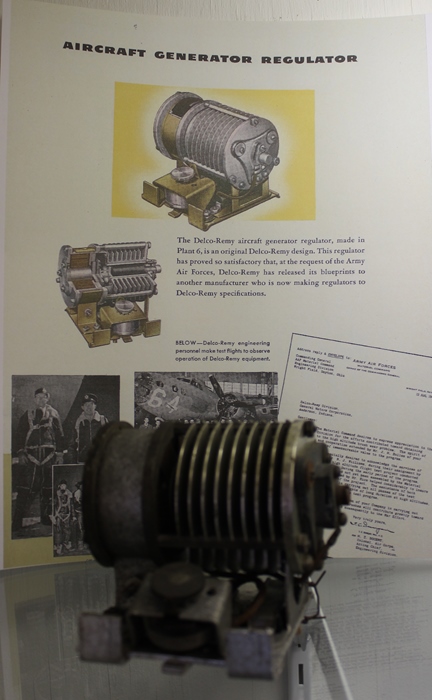

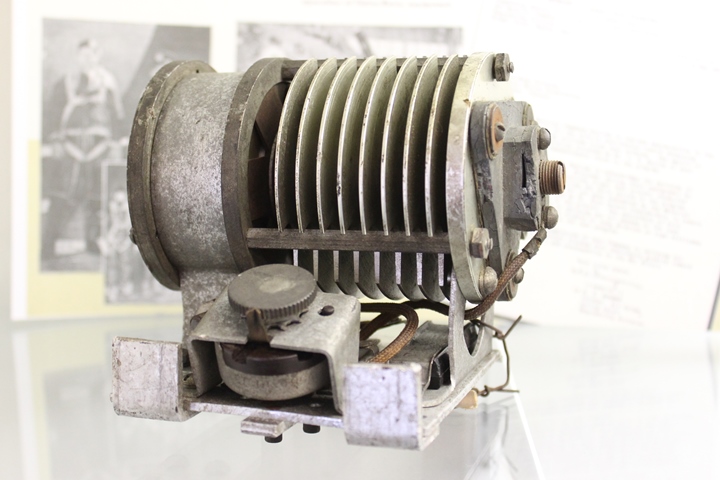

Aircraft Generator Carbon Pile Voltage Regulator: Delco-Remy developed a carbon pile type aircraft regulator that did not generate any electrical or radio interference like the more common point contact regulator did. It was so successful that the Army Air Force requested that Delco-Remy license other manufacturers to build it for the war effort. Delco-Remy had the best design for this device.

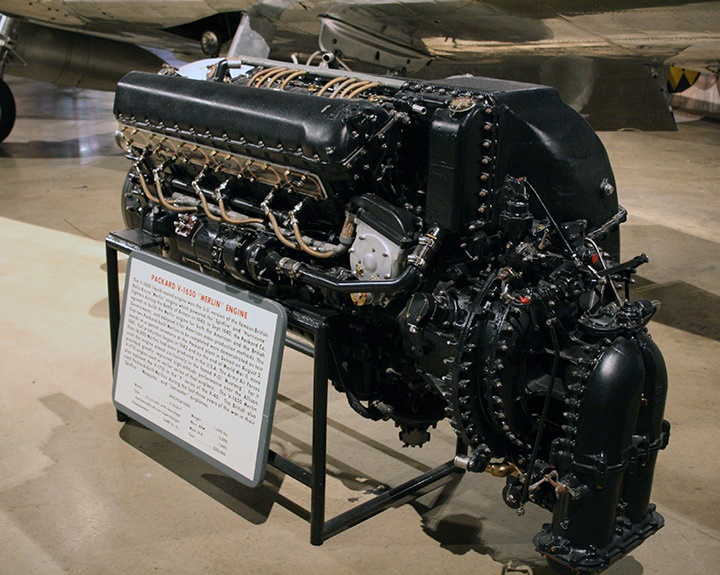

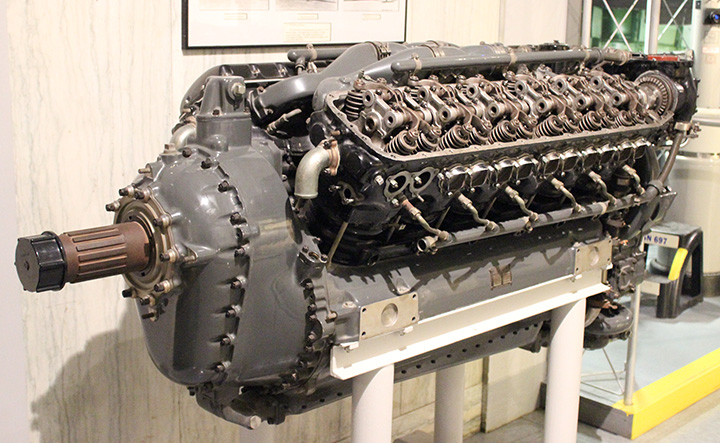

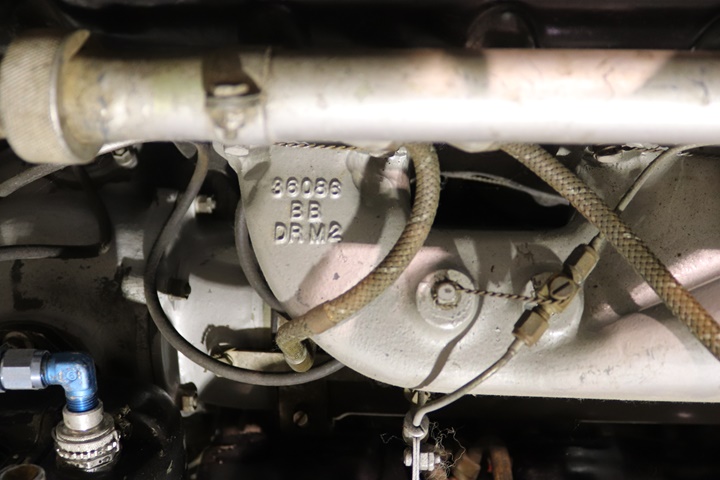

Packard-built Rolls-Royce V-1650 Aircraft Engine: According to the March 9, 1945 edition of the 'Delco-Remy Clan,' the Bedford, IN foundry had received new contracts for increasing production on the Rolls-Royce aircraft engine. This implies that Bedford had already been producing casting for the Packard-built Rolls-Royce V-1650 Merlin engine. This is the only reference I have ever seen that Delco-Remy was supplying castings to any other aircraft engine manufacturer besides Allison. The Packard-built Merlin engine was the most important and best inline engine used in an Army Air Force fighter during World War Two. It made the P-51 Mustang into the best Army World War Two fighter aircraft.

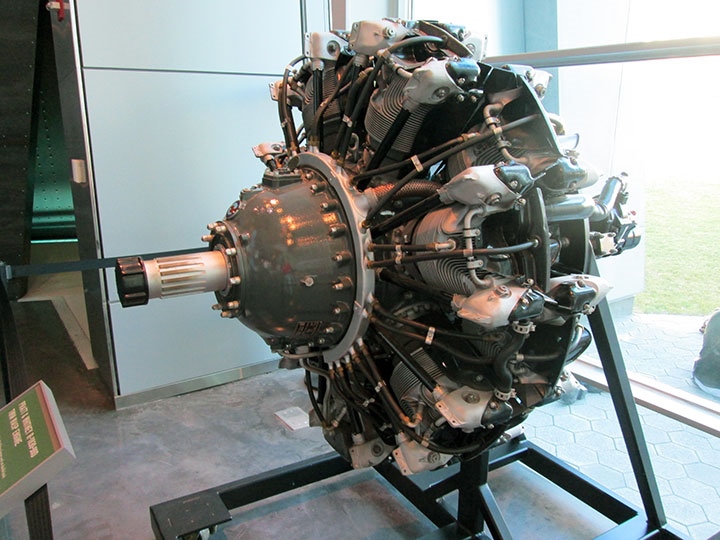

The Allison V-1710 Aircraft Engine:

The photos below show aircraft that were powered by the Allison V-1710 engine which had Delco-Remy castings.

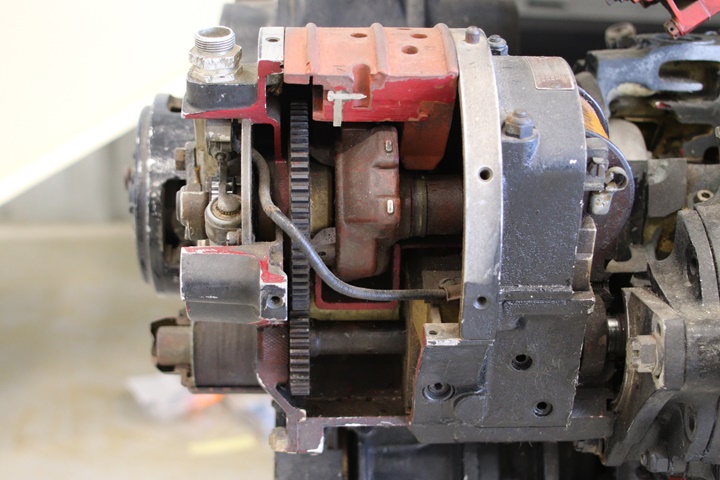

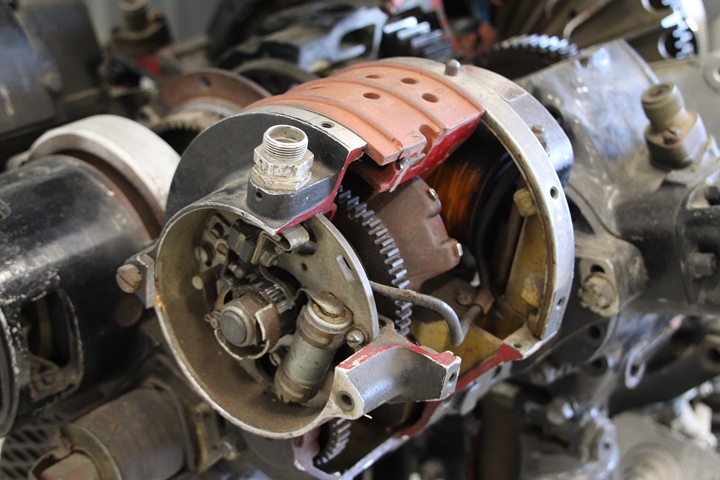

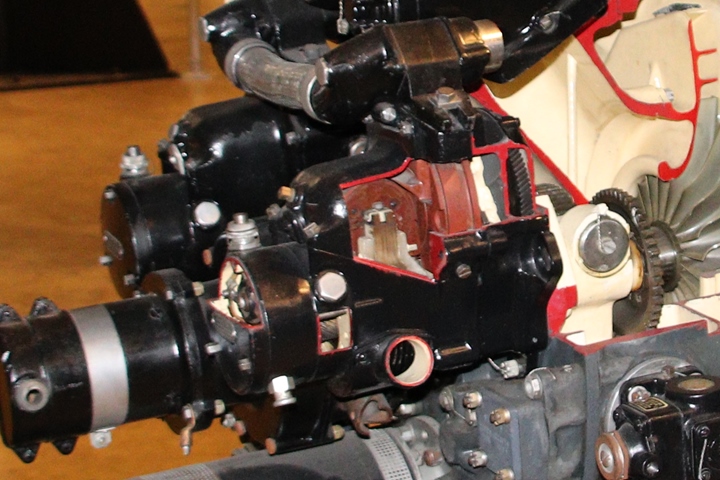

The Delco-Remy-built American Bosch Aircraft Magneto: Delco-Remy became a licensed supplier of American Bosch aircraft magnetos for the Army Air Force during World War Two. In July 1942, initial contact was made between the two companies that resulted in Delco-Remy building more than 295,000 magnetos for the war effort. By April 1943, Delco-Remy was running 15,000 magnetos a month in Plant 10. The coils were built in Plant 1 and the molded parts in Plant 2. By early 1943, known Delco-Remy Bosch magneto customers were Chevrolet, Studebaker, and Jacobs. All built aircraft engines during World War Two. I have looked at a considerable number of aircraft engines in many aviation museums attempting to find an example of Delco-Remy Bosch type magneto. I finally found two of them on a Sunday afternoon as I was visiting the Waco Museum in Troy, OH. The engine was all the way in the back corner of the museum's second display building. There were two 1943 Delco-Remy magnetos on a Pratt & Whitney 985 Wasp Junior engine.

The Allison V-3420 Twenty-four Cylinder Aircraft Engine:

The Allison Aircraft Jet Engine: According to the March 30, 1945 "Delco-Remy Clan," Plant 7 had been and was providing jet engine castings to Allison. Due to the secrecy of the project, this was the first time it had been announced to the employees and public. The April 13, 1945 "Clan" indicated the Allison-built jet engines were being produced for the Lockheed P-80, the first operational jet aircraft for the U.S. Army Air Force. The engine was a GE-designed J-33 centrifugal flow jet engine that Allison was building under license. Allison built 297 J-33s by the end of the war.

|