|

Delco-Remy in WWII

Delco-Remy WWII Aircraft

Products

Delco-Remy WWII Marine

Equipment

Delco-Remy WWII Tank Products

Delco-Remy WWII Vehicle Products

Delco-Remy and LST-393

Delco-Remy WWII King's Mill

Plant

Delco-Remy WWII Antioch

Foundry

Delco-Remy WWII Stationary Engine Products

Delco-Remy WWII

Electrical Components for the Reo and Federal Truck, 20-Ton, 6x4

Delco-Remy Training Manuals for Aircraft Components

Delco-Remy in World War Two

World War Two Products and

Product Applications

This page updated

4-21-2025.

This is one of four pages

on this site to exhibit the contributions of Delco-Remy Division of GM

in

winning the World War Two. "Delco-Remy at the Normandy Invasion"

details the contribution of the Division during this historic amphibious

invasion. "Our War Job" is the complete reproduction Delco-Remy's

1944 booklet detailing its participation in the war effort up to that

date. "The Army-Navy "E" Award with Three Stars" page is a photo

essay of Delco-Remy's World War Two "E" flag. This page, "World

War Two Products and Product Applications," complements the other three

pages, by providing more detail on the many pieces of equipment which

used Delco-Remy electrical components. Many of these pieces of

equipment were not at the Normandy Invasion. They were

either introduced into the European combat zone after the initial

landings, or obsolete as front line fighting weapons prior to D-Day.

This page has eight more

pages linked at the top that provide more extensive information on

Delco-Remy World War Two products and their applications. There is

too much information to add to one page.

Prior to World War Two,

Delco-Remy not only supplied General Motors cars and trucks with

electrical components, but also supplied other car and truck makers as

well. Even before the United States entered World War Two after

Pearl Harbor, Plant 7 was built in 1940 as an aluminum foundry to

produce castings for the Allison V-1710 aircraft engine. This page shows

many of Delco-Remy (D-R) products used in a plethora of military

applications during World War Two. Product applications fell into four

basic groups: trucks, tracked and wheeled armored vehicles, small

boats and landing craft, and aircraft engines and equipment.

The information on this

and the other eight related pages is not comprehensive but what is known

of applications for Delco-Remy

products during World War Two. There were so many, and after 80

years, it is difficult to find all of the war products D-R built.

This, and the associated application pages, are a good snap-shot of how

Delco-Remy helped win World War Two.

This is the original Anderson Delco-Remy Army Navy "E" Flag that the Division

won during World War Two. This historical treasure was saved for posterity

and was photographed at the Madison County Historical Society's 2016

Delco-Remy display. Authors' photo.

The Army-Navy "E" Award was the most sought after award during World

War Two.

Only 5% of the eligible companies received it. Of those 5%, only 18%

were awarded three stars like D-R Anderson. D-R Anderson

originally won the Army-Navy "E" Award on May 4, 1943. The stars

were added on February 26, 1944, September 9, 1944, and

April 21, 1945.

Delco-Remy

World War Two Products: Table 1 shows that Delco-Remy had a

total of $53,221,000 in major contracts during World War Two. This

total shows the contracts amounts for Anderson, IN, Muncie, IN, and King

Mills, OH. Tables 2 through 5 show the individual contracts for

each of the three locations.

Table 1 - Delco-Remy Division's Major World War Two Contracts

- Total for All Plants

Added 4-21-2025.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division.

|

|

Location |

Contract Amount |

| Anderson, IN |

$45,622,000 |

| Muncie, IN |

$5,523,000 |

| Kings Mills,

OH |

$2,076,000 |

| Total |

$53,221,000 |

Table 2 - Delco-Remy Division's Major World War Two Contracts

- Anderson, IN Plants

Added 4-21-2025.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Solenoid

Assemblies - USAAF |

535-AC-17676 |

$80,000 |

3-1941 |

11-1941 |

| Assemblies

Generator - USAAF |

535-AC-19649 |

$356,000 |

6-1941 |

3-1942 |

| Generator

Assemblies - USAAF |

535-AC-20917D |

$1,531,000 |

9-1941 |

5-1943 |

| Generator

Assemblies - USAAF |

535-AC-20900D |

$1,115,000 |

9-1941 |

11-1942 |

| Starters

Generators - Army Ordnance |

294-ORD-795 |

$267,000 |

10-1941 |

5-1942 |

| Generators -

Army Ordnance |

294-ORD-835 |

$173,000 |

3-1942 |

6-1942 |

| Cable Systems

90mm AA - Army Ordnance |

294-ORD-956 |

$14,614,000 |

3-1942 |

4-1943 |

| Motors

Electrical Servo - USAAF |

535-AC-26141 |

$79,000 |

4-1942 |

12-1942 |

| Regulators -

USAAF |

535-AC-26961D |

$339,000 |

6-1942 |

6-1943 |

| Air

Compressor Parts - Army Corps of Engineers |

214-ENG-236 |

$50,000 |

7-1942 |

8-1942 |

| Generator

Assys - USAAF |

535-AC-27802 |

$1,654,000 |

8-1942 |

6-1944 |

| Generators -

USAAF |

535-AC-32312 |

$67,000 |

9-1942 |

5-1943 |

| Starter

Motors - Army Ordnance |

294-ORD-1530 |

$608,000 |

10-1942 |

9-1943 |

| Generators -

USAAF |

535-AC-33621 |

$50,000 |

11-1942 |

4-1943 |

| Generator

Assys - USAAF |

535-AC-33161 |

$12,239,000 |

11-1942 |

12-1943 |

| Generator

Assemblies - USAAF |

535-AC-33968 |

$3,335,000 |

2-1943 |

12-1943 |

| Generator

Parts - USAAF |

535-AC-37743 |

$80,000 |

2-1943 |

8-1943 |

| Generators -USAAF |

2229-AC-43 |

$78,000 |

2-1943 |

11-1943 |

| Electrical

Equipment - USAAF |

535-AC-35765 |

$157,000 |

2-1943 |

12-1943 |

| Batteries -

Navy |

S-10212 |

$94,000 |

2-1943 |

11-1943 |

| Communication

Equipment - Army Signal Corps |

3435-SC-330 |

$50,000 |

6-1943 |

4-1944 |

| Voltage

Regulators - USAAF |

33038-AC-290 |

$825,000 |

8-1943 |

7-1944 |

| Generator

Assys - USAAF |

20017-AC-57 |

$1,564,000 |

9-1943 |

6-1944 |

| Elec

Generator Assys - USAAF |

30053-AC-347 |

$486,000 |

12-1943 |

10-1944 |

| Batteries -

Army Ordnance |

33008-ORD-693 |

$205,000 |

1-1944 |

12-1944 |

| Ordnance

Equipment - Army Ordnance |

33008-ORD-590 |

$74,000 |

2-1944 |

10-1944 |

| Storage

Batteries - USAAF |

33038-AC-2021 |

$69,000 |

2-1944 |

10-1944 |

|

Regulators - USAAF |

33038-AC-1784 |

$429,000 |

2-1944 |

5-1945 |

| Industrial

Truck Parts - Army Quartermaster Corps |

12036-QM-3896 |

$56,000 |

3-1944 |

2-1945 |

| Ordnance

Equipment - Army Ordnance |

33008-ORD-624 |

$123,000 |

3-1944 |

1-1945 |

| Electric Gen

Assys - USAAF |

33038-AC-1789 |

$1,156,000 |

3-1944 |

4-1945 |

| Ordnance

Equipment - Army Ordnance |

33008-ORD-958 |

$231,000 |

5-1944 |

5-1945 |

| Motor Vehicle

Parts - U.S. Treasury Deparment |

TPS-55774L |

$154,000 |

6-1944 |

10-1944 |

|

Generator Assys - USAAF |

33038-AC-2908 |

$728,000 |

6-1944 |

10-1945 |

| Storage

Batteries - Army Ordnance |

33008-ORD-1298 |

$258,000 |

8-1944 |

5-1945 |

| Electrical

Equipment - Army Ordnance |

33008-ORD-1520 |

$70,000 |

9-1944 |

7-1945 |

| Electrical

Equip - Army Ordnance |

33008-ORD-1519 |

$268,000 |

9-1944 |

9-1945 |

| Motor

Generator Parts - Army Ordnance |

33008-ORD-1781 |

$285,000 |

12-1944 |

7-1945 |

| Batteries -

Army Ordnance |

33008-ORD-1690 |

$1,608,000 |

12-1944 |

7-1945 |

| Generator

Parts - Army Corps of Engineers |

33017-ENG-660 |

$64,000 |

12-1944 |

6-1945 |

| Diesel

Starting Motors - Navy |

OBS-20235 |

$101,000 |

1-1945 |

7-1945 |

| Motor Vehicle

Parts - Navy |

OM-47260 |

$60,000 |

1-1945 |

7-1945 |

| Electric

Generators Motors - Army Corps of Engineers |

33017-ENG-1966 |

$65,000 |

3-1945 |

10-1945 |

| Electric Gen

Assys - USAAF |

33038-AC-8976 |

$226,000 |

5-1945 |

12-1945 |

| Generator

Assys - USAAF |

33038-AC-8503 |

$607,000 |

5-1945 |

12-1945 |

| Voltage

Regulators - USAAF |

33038-AC-9778 |

$617,000 |

5-1945 |

3-1946 |

| Voltage

Regulators - USAAF |

33038-AC-8391 |

$363,000 |

5-1945 |

8-1945 |

| Electrical

Equip - Army Quartermaster Corps |

12036-QM-18689 |

$148,000 |

6-1945 |

6-1946 |

| Total |

|

$47,856,000 |

|

|

| Minus

Batteries built in Muncie Awarded to Anderson. From

Table 3. |

|

$2,234,000 |

|

|

| Corrected

Anderson-built Total |

|

$45,622,000 |

|

|

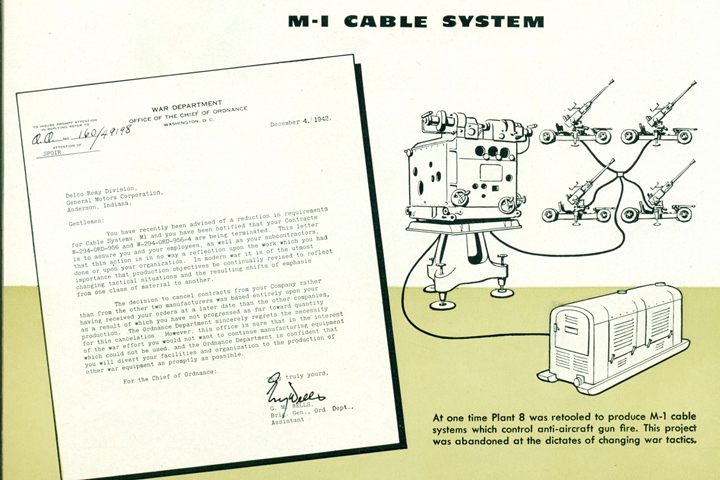

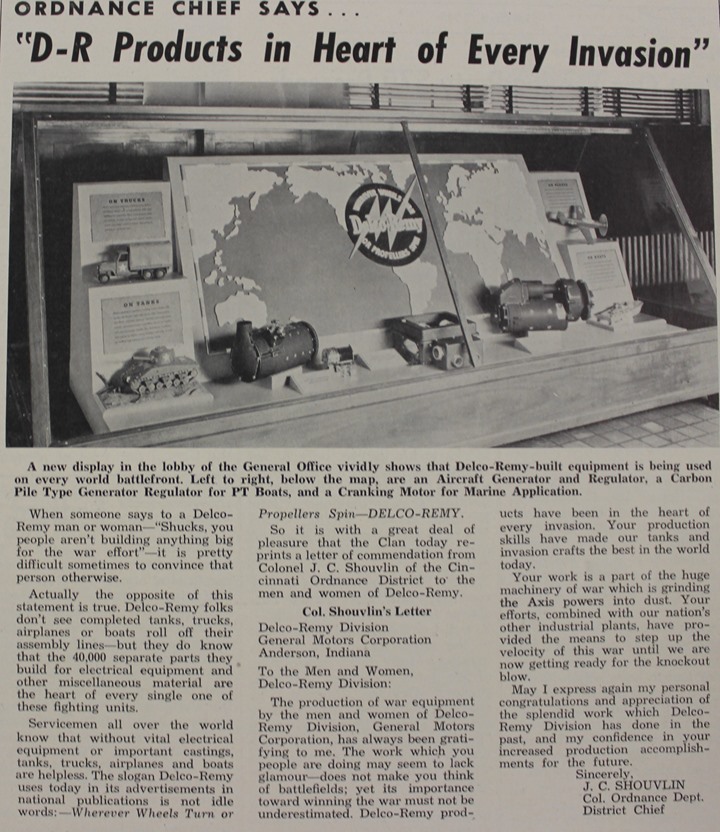

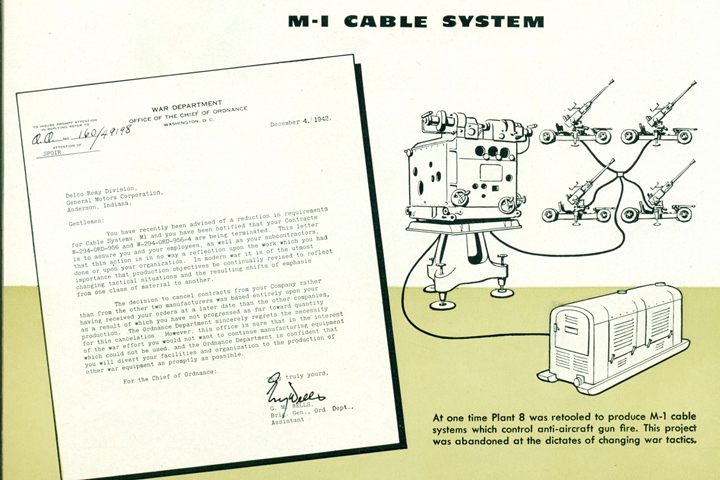

Of special interest in Table

2 is contract Army Ordnance contract number 294-ORD-956 for $14,614,000

for 90mm anti-aircraft gun cables. The $14,614,000 is 32% of the

total contracts awarded to the Anderson plants. What is of special

interest is that cables were not a Delco-Remy core product like the

generators, regulators, and starters that were contracted to the

Anderson plants. As the information from "Our War Job" below

shows, Plant 8 was in the process of tooling up for this project when it

was cancelled. Because this was not a core product, Delco-Remy had

to have sub-contractors provide the components for final assembly in

Plant 8. No doubt this was part of the reason why the project was

cancelled, as this was a timely process.

Image added 4-21-2025.

The Delco-Remy document shows 40mm

anti-aircraft guns using the cable. The contract was for M-1

cables to be used with 90mm anti-aircraft guns like the one shown here.

Author's photo added 4-21-2025.

Table 3 - Delco-Remy Major World

War Two Battery Contracts awarded to the Anderson, IN Plants but

actually built in the Muncie, IN Battery Plant

Added 4-21-2025.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Batteries -

Navy |

S-10212 |

$94,000 |

2-1943 |

11-1943 |

| Batteries -

Army Ordnance |

33008-ORD-693 |

$205,000 |

1-1944 |

12-1944 |

| Storage

Batteries - USAAF |

33038-AC-2021 |

$69,000 |

2-1944 |

10-1944 |

| Storage

Batteries - Army Ordnance |

33008-ORD-1298 |

$258,000 |

8-1944 |

5-1945 |

| Batteries -

Army Ordnance |

33008-ORD-1690 |

$1,608,000 |

12-1944 |

7-1945 |

| Total |

|

$2,234,000 |

|

|

Table 4 - Delco-Remy Division's Major World War Two Contracts

- Muncie, IN Battery Plant

Added 4-21-2025.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

|

Batteries Storage - Naval Aeronautics |

XSA-13364L |

$249,000 |

10-1942 |

2-1944 |

|

Batteries - U.S. Treasury Department |

TPS-22801L |

$101,000 |

12-1942 |

7-1943 |

|

Batteries - Army Ordnance |

294-ORD-2212 |

$163,000 |

3-1943 |

3-1944 |

|

Batteries - Navy |

288-S-17403 |

$122,000 |

10-1943 |

6-1944 |

|

Batteries - Navy |

288-S-18261 |

$171,000 |

11-1943 |

11-1944 |

|

Battery Vent Caps - Navy |

288-S-20416 |

$74,000 |

2-1944 |

8-1944 |

| |

33008-ORD-760 |

$323,000 |

3-1944 |

4-1945 |

|

Batteries - U.S. Treasury Department |

TPS-52225L |

$92,000 |

3-1944 |

6-1944 |

|

Storage Battery Caps - Naval Aeronautics |

288-XSA-21862 |

$185,000 |

4-1944 |

9-1944 |

|

Storage Batteries - Naval Aeronautics |

288-XSA-22102 |

$290,000 |

4-1944 |

5-1945 |

| Storage

Batteries - Naval Aeronautics |

288-XSA-22479 |

$182,000 |

4-1944 |

12-1945 |

| Storage

Batteries - Army Ordnance |

33008-ORD-714 |

$60,000 |

5-1944 |

9-1944 |

| Storage

Batteries - Army Ordnance |

33008-ORD-1269 |

$143,000 |

8-1944 |

5-1945 |

|

Dry Cell Batteries - Army Ordnance |

33008-ORD-1850 |

$250,000 |

11-1944 |

6-1945 |

|

Storage Batteries - Naval Aeronautics |

XSA-95379 |

$352,000 |

3-1945 |

4-1946 |

|

Storage Batteries - Naval Aeronautics |

XSA-95423 |

$154,000 |

4-1945 |

6-1945 |

|

Battery Vents - Naval Aeronautics |

288-XSA-33087 |

$108,000 |

6-1945 |

1-1946 |

|

Total |

|

$3,019,000 |

|

|

| Plus

Batteries built in Muncie Awarded to Anderson. From

Table 3. |

|

$2,234,000 |

|

|

| Corrected

Muncie-built Total |

|

$5,523,000 |

|

|

Table 5 - Delco-Remy Division's Major World War Two Contracts

- Kings Mill, OH Landing Craft Starter Motor Plant

Added 4-21-2025.

The information below

comes from the "Alphabetical Listing of Major War Supply

Contracts, June 1940 through September 1945." This was

published by the Civilian Production Administration, Industrial

Statistics Division. |

|

Product - Customer |

Contract Number |

Contract Amount |

Contract Awarded

|

Completion

Date |

| Diesel Engine

Motors - Navy Ships Bureau |

OBS-14704 |

$2,076,000 |

5-1944 |

6-1945 |

|

Total |

|

$2,076,000 |

|

|

During World War Two, companies were not

allowed to publicly publish production numbers, as they were

considered to be a military secret. In 1945 these regulations

eased up. In the February 9,1945 edition of the "Delco-Remy Clan,"

Delco-Remy was allowed to release production numbers of World War Two products to

date. The numbers are shown by general product groups and not by

individual product; but they do give an insight into the amount of war material D-R

produced up until early 1945.

The plants included in the production of the following parts were

Anderson, IN; Bedford, IN; Kings Mill, OH; Muncie, IN; and Yellow

Springs, OH. No specifics are given below for the number of

batteries produced by Muncie.

1,500,000+ electrical sets consisting of generators, cranking motors,

regulators, switches, distributors and coils for military trucks,

tractors and DUKWs.

485,000+ heavy duty of generators, cranking motors, regulators, coils

and switches for Army tanks and tank destroyers and for Navy landing

craft and PT boats.

105,000+ aircraft generators and regulators.

295,000+ aircraft magnetos. Two magnetos were used per aircraft

engine. During World War Two, 812,615 aircraft engines were produced.

DR supplied over 147,500 or 18% of them with magnetos.(62,000+ aircraft engine controls.

40,000+ Sperry automatic pilot servo controls.

60,000+ complete sets of aluminum castings for the Allison V-1710 and

V-3420 aircraft engines. Allison produced (69,305) V-1710 and

V-3420 engines during World War Two.

-

Further research indicates that Delco-Remy

also supplied:

2,196 marine pitch propeller controls for 1,098 Landing Craft,

Infantry, (Large) and 544 units for 243 110-foot subchasers.

-

There was an unknown amount of supercharger blowers

produced for Detroit Diesel Division of

General Motors 6-71 engines that were used on Sherman tanks, Wolverine

tank destroyers, and most small landing craft used in World War Two.

In July 1943 Delco-Remy had a run rate of 6,500 blowers per month.

|

Delco-Remy World War Two Products by Plant

|

| Plant |

Product |

World War Two Document |

Comments |

| 1 |

Marine propeller pitch control switch, aircraft

magneto coils, bomber trim tab controls |

Propeller Shifter Switch |

|

| 2 |

Aircraft magneto molded parts and breaker

assemblies |

|

|

| 3 |

Marine propeller pitch control motor |

|

|

| 4 |

Servo bodies for aircraft auto-pilots |

|

|

| 5 |

Various castings |

|

|

| 6 |

Contact point regulators, Carbon pile aircraft

regulators, automatic engine control |

Carbon Pile Regulators |

|

| 7 |

Aluminum foundry for aircraft castings |

|

Allison V-1710 aircraft engine |

| 8 |

Aircraft generators |

|

|

| 9 |

Steel tubing, aircraft storage batteries,

supercharger blowers |

|

Steel tubing for fuel, oil, air, brake,

refrigerator, and electrical conduit |

| 10 |

Bosch aircraft magnetos, aircraft machined parts |

|

|

| Yellow Springs, OH (Antioch) |

Aluminum foundry for aircraft castings,

experimental casting work |

|

|

| Bedford, IN |

Aluminum foundry for aircraft castings |

|

|

| Midwest |

Packaging and shipping |

|

|

| Kings Mill, OH |

Marine starter motors for landing craft |

|

|

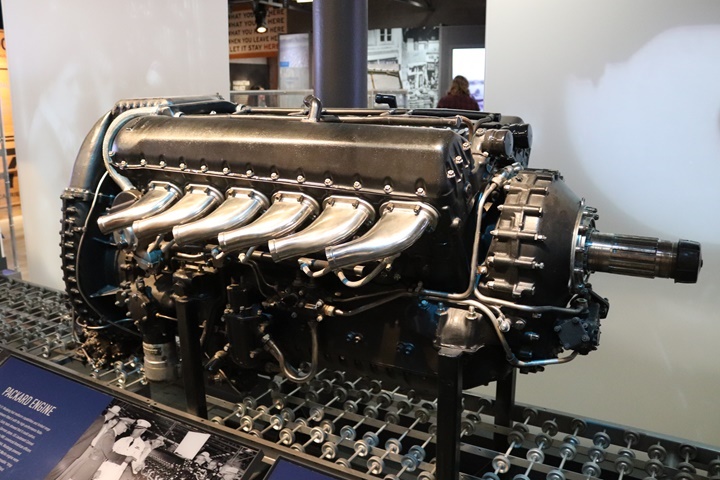

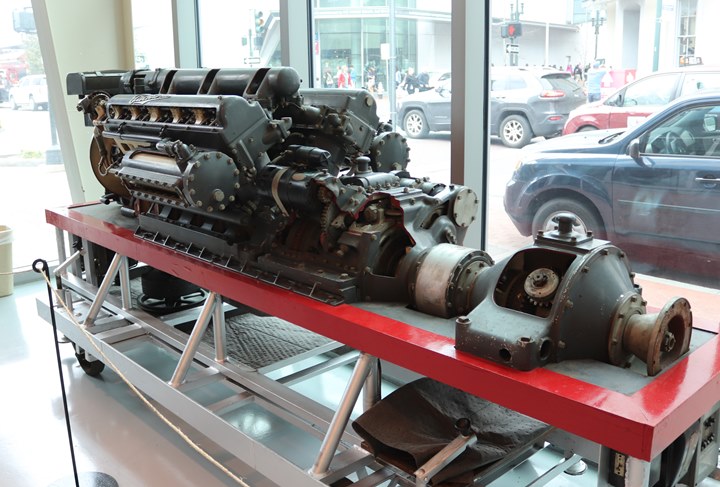

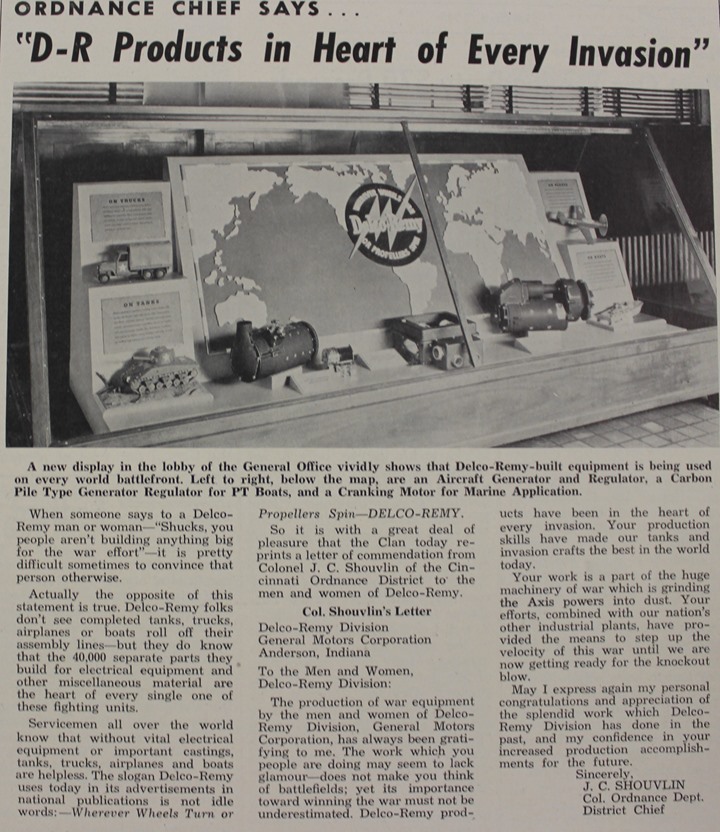

PT-305:

PT-305 is the only operating Higgins-built

PT boat that is a World War Two combat veteran. The three 1,500 hp Packard

marine engines have D-R cranking motors and DC generators.

Author's photo added 3-29-2018.

The National World War Two Museum in

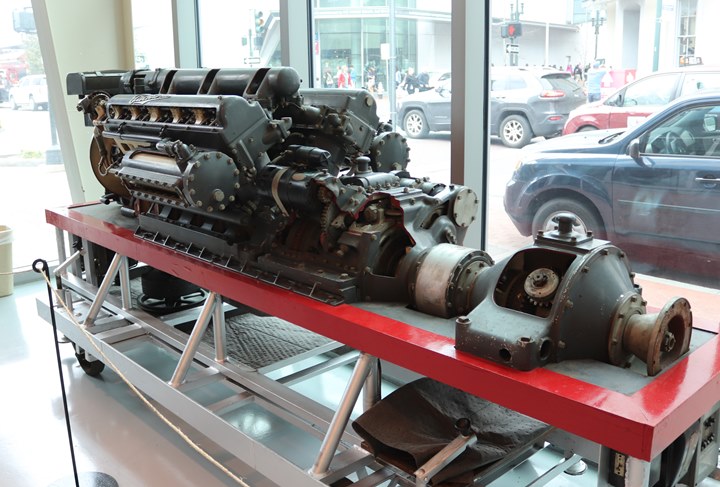

downtown New Orleans, LA has this cut-a-way of a Packard marine engine

on display which was used to power the World War Two PT boats. A Delco-Remy

starter is prominently displayed on the engine.

Author's photo added 3-29-2018.

LST-393:

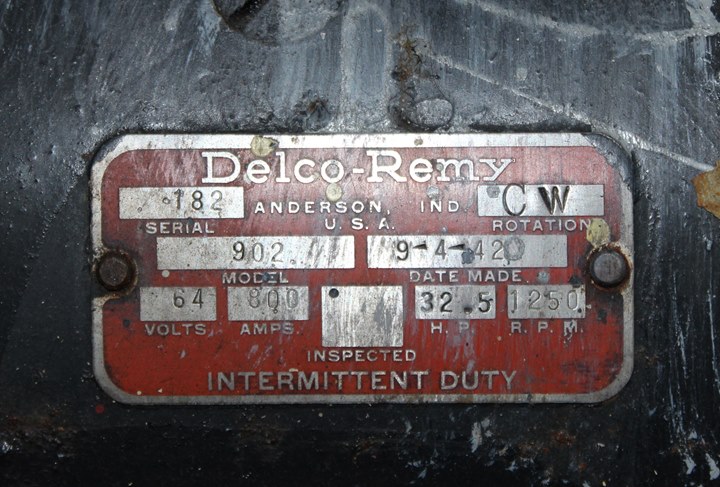

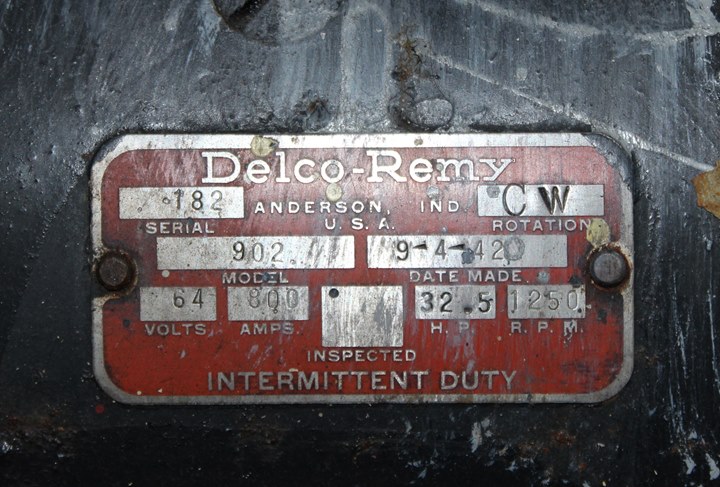

Now this is a Delco-Remy cranking motor!!!

Note the size of the motor compared to the author's size 9-1/2 shoe.

It took this size of a cranking motor to start the Electro-Motive 900 hp

diesel engine on US Navy LST landing ships. This and a second D-R

starter can be seen on LST 393 in Muskegon, MI. Author's photo.

The Delco-Remy ID Tag shows that this was

Serial Number 182 and built on 9-4-1942. This 64 volt starter

pulled 800 amps to produce 32.5 hp. This is the largest D-R

cranking motor the author has ever seen. For more photos and

information see my

D-R World War Two LST 393 page. Author's photo.

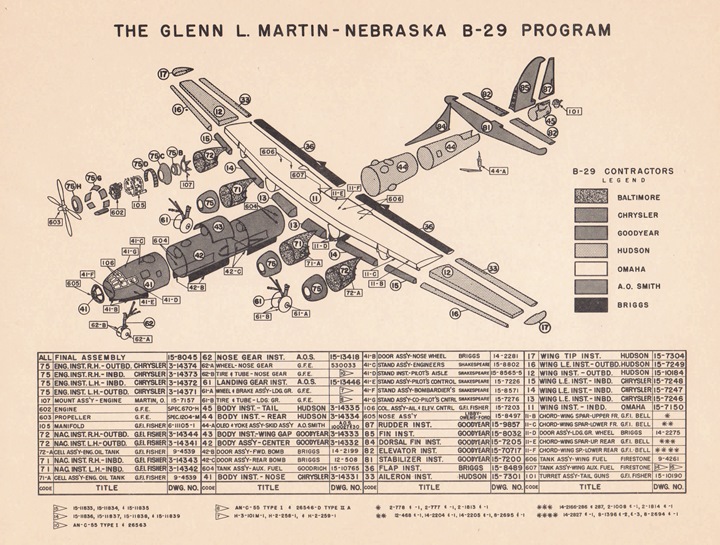

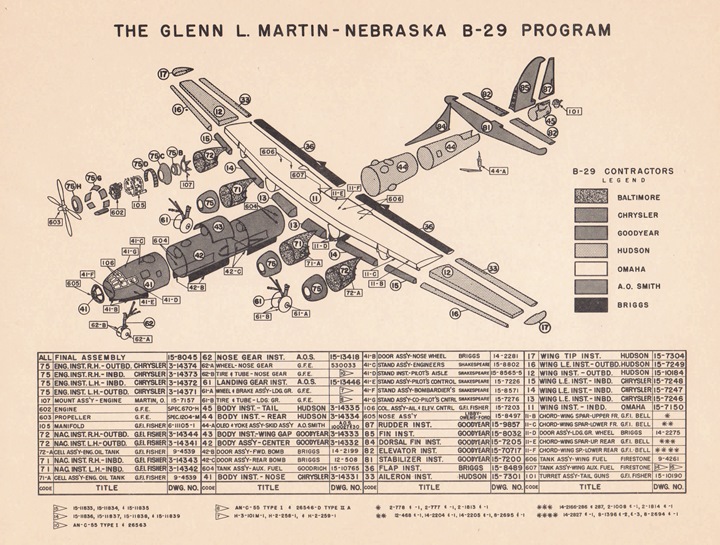

The B-29 Project: Delco-Remy was

one of seventeen GM Divisions that built components for the B-29.

It was the most expensive project of World War Two, being even more expensive

than the Manhattan Project.

No mention of the B-29 is made in the 1944

Delco-Remy booklet "Our War Job". There are two reasons for this.

First, production on the B-29 did not start until mid-1944, and

contracts and tooling were still being made when the booklet was

published. Second, the B-29 project was considered "Top Secret."

Delco-Remy would have only been able to state it was working on the

project, but not what the project was. As diverse as Delco-Remy

produced

aircraft-related products were during World War Two, the Division

could have supplied any number of components for the B-29.

This Glenn Martin Company document shows the major airframe suppliers

for its plant in Omaha, NE. This was one of four plants that

produced the B-29 during World War Two. The Omaha plant relied on

the American auto industry for many of the components for the B-29s it

built.

Starting at the front of

the fuselage and working towards the rear of the aircraft, the glass

nose section was built by Libby-Owens-Ford, an automotive glass company.

The fuselage nose section was built by Chrysler's Plymouth Division in

Detroit. Goodyear in Akron, OH built the two bomb bay fuselage

sections. Briggs, an independent auto body manufacturer in

Detroit, provided the bomb bay doors. The three rear fuselage

sections behind the wings were also built in the city of Detroit by the

Hudson Motor Car Company, which combined with Nash in 1954 to become

American Motors. The entire tail section and the elevators with

control surfaces were made by Goodyear, and the tail gunner's position

was manufactured by the Fisher Body Division of GM at Cleveland, OH.

Martin Omaha provided the

center section of the wing. Chrysler provided the inboard leading

edges. Hudson built the outer wing sections, outer leading edges,

ailerons, and wing tips. Briggs provided the flaps. All four

engine nacelles and engine oil tanks came from the Fisher Body Division

of GM along with the exhaust manifolds. Omaha built the engine

mounts; Dodge supplied the engines and Chrysler the engine cowlings.

Firestone provided the

main and auxiliary wing fuel tanks. BF Goodrich provided the fuselage

auxiliary fuel tank.

While this is a Boeing-designed aircraft, there are no major fuselage, wing

nor rear tail

section components provided by that company for the Martin Omaha-built

B-29s. With the exception of

the Martin wing center section, the rest of the wing was supplied by the

American automobile industry.

Inside the B-29 airframe

and wing structural components listed above, there were tens of

thousands of parts and components. The engine nacelles produced by

the Fisher Body Division of GM had over 3,000 parts in them. Each

nose fuselage section built by Chrysler had 5,000 parts in it.

Many of the parts for many of the major components would have been

supplied by AC Sparkplug, Allison, Brown-Lipe-Chapin, Buick, Chevrolet,

Delco Appliance, Delco Products, Delco Radio, Delco-Remy, Fisher Body,

Frigidaire, Harrison Radiator, Hyatt Bearings, Moraine Products, New

Departure, Packard Electric, and Rochester Products Divisions of GM as

identified in the 1944 GM Annual Report.

Of significance is that

the Martin Plant in Omaha, NE produced the Silverplate B-29 Nuclear

Bombers.

No doubt some Delco-Remy part or component

went on a ride to Hiroshima, Japan in the Enola Gay on August 6, 1945.

Author's photo.

Delco-Remy

World War Two Products as listed in "Our War Job:" Electrical Components for

Military Trucks - Generators and generator regulators, starting motors,

ignition distributors and coils, switches, and batteries; Electrical

Components for Military Tanks and Armored Vehicles - Generators and

generator regulators, starting motors, ignition distributors and coils,

apparatus boxes, and batteries; Electrical Components for Military

Aircraft - Generators and generator regulators, magnetos, and batteries;

Automatic Aircraft Engine Controls; Solenoids for Sperry Autopilots;

Automatic Trim Tab Controls; Electrical Components for Military Marine

applications - Generators and generator regulators, starting motors,

ignition distributors and coils; Marine propeller pitch controls

for landing craft and submarine chasers; Marine diesel equipment -

pistons, blowers, pre-heaters and pre-heater fuel pumps, governors;

Tubing - for electrical, fuel, brake, air conditioning, oil and air

lines; Allison V-1710 engine castings - Various; Aircraft engine

machined parts - Various; (1,000,000) 20mm shell bodies; Various

solenoids for starting motors, aircraft bomb release racks, guns and

overdrive controls.

Delco-Remy manufactured one million 20mm

shell projectiles. The U.S. Navy was the primary user of the 20mm

cannon during World War Two. Author's photo added 5-8-2020.

Delco-Remy

World War Two Products at the Madison County Historical Society:

The Madison County Historical Society in Anderson, IN has an excellent

collection of Delco-Remy-built World War Two era components. Below

are photos from the 2016 Delco-Remy exhibit at the historical society.

Some of the parts are experimental, and others production items.

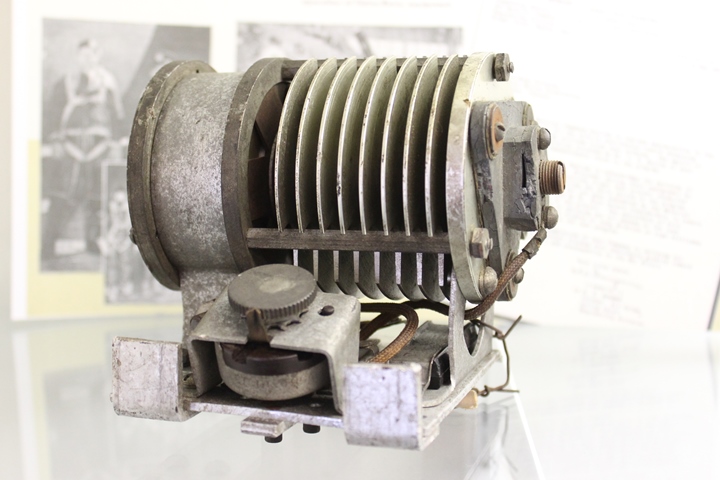

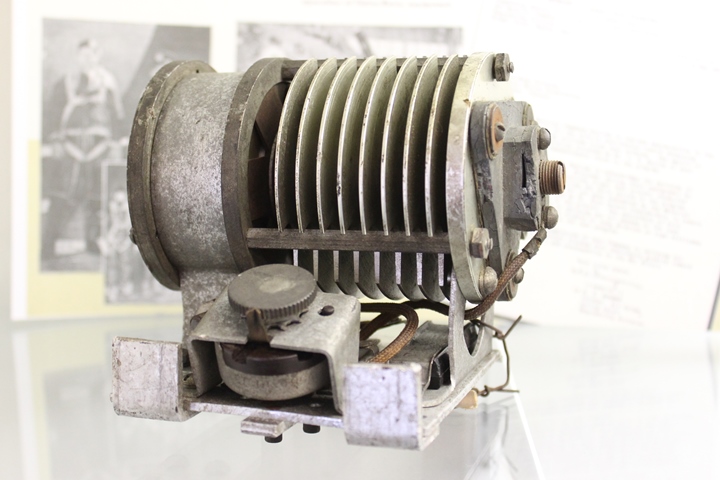

This is a carbon pile aircraft regulator.

It was developed by Delco-Remy. At the request of the U.S. Army

Air Force, Delco-Remy then licensed to other manufacturers to assure an

adequate supply. Author's photo added 5-8-2020.

This is an experimental hydrogen filled

distributor model number EX-38983. Author's photo added 5-8-2020.

Model number EX-38983 as seen from the

bottom. Author's photo added 5-8-2020.

Experimental four-cylinder magneto with

partial model number EX-3674x. It is of 1941 vintage.

Author's photo added 5-8-2020.

Ignition coil 1115143 is also part of the

collection. Author's photo added 5-8-2020.

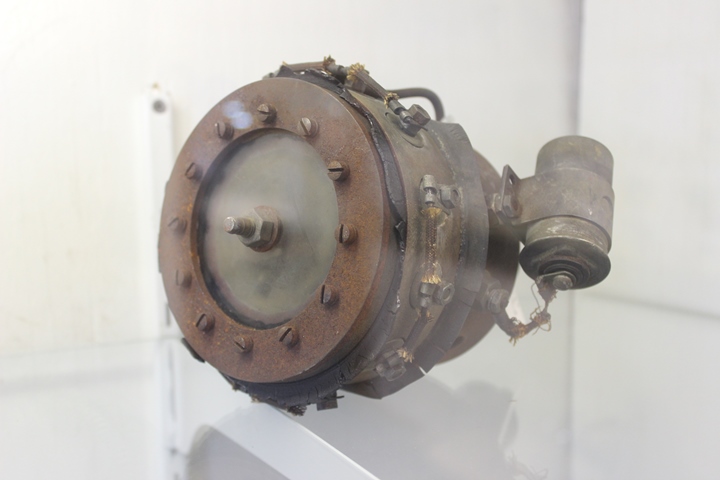

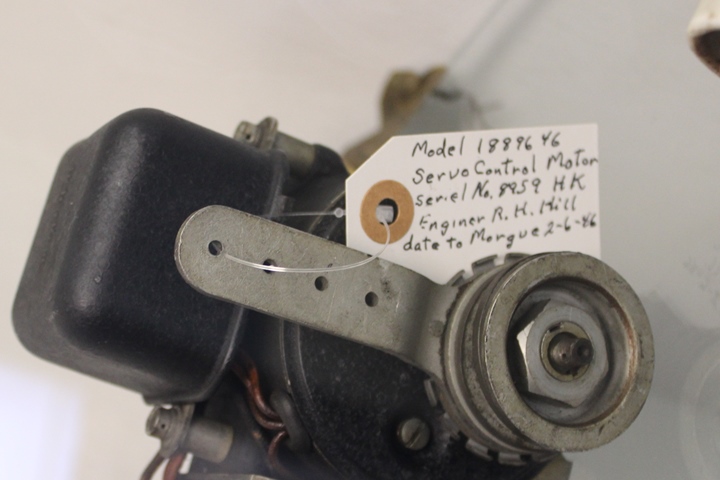

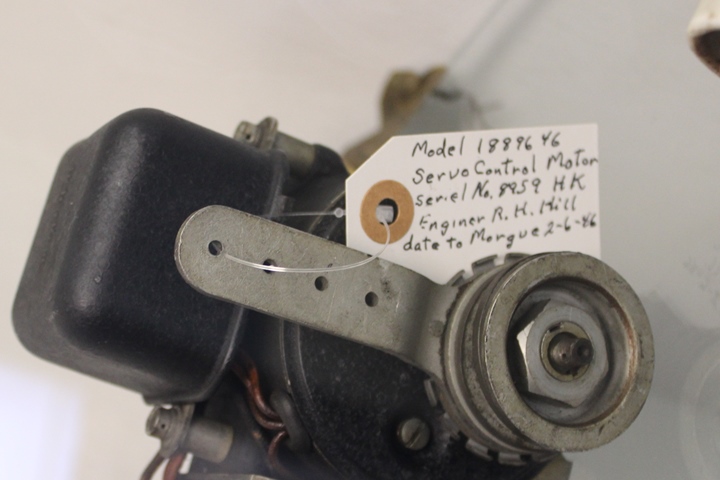

The servo control motor on display at the

Historical Society is model number 1889646 with serial number 8959hk. This

was part of the Sperry auto-pilot that Delco-Remy produced for such aircraft

as the B-24 Liberator bomber. Author's photo added 5-8-2020.

Author's photo added 5-8-2020.

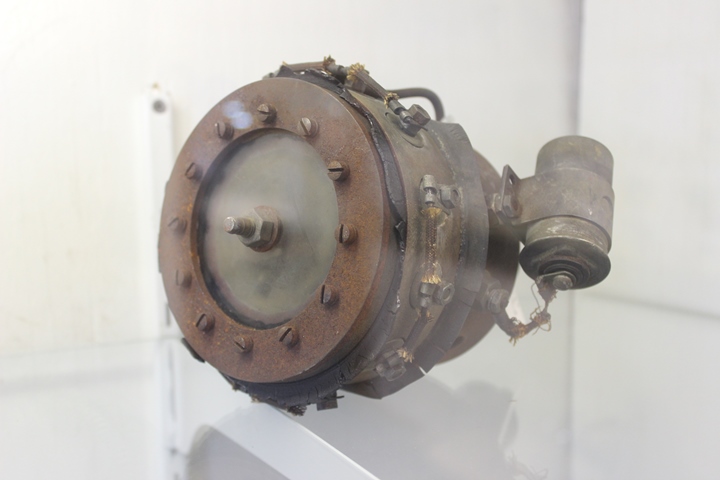

World War Two Experimental Alternator:

This Delco-Remy engineering sample was found on the 1943 Chevrolet

Airborne Extra-Light 1/4-Ton Jeep Program. More photos and

information can be found on the

Delco-Remy Military

Truck page.

This has all of the appearances of a

Delco-Remy alternator. Author's photo added 5-8-2020.

Delco-Remy Clan Photos:

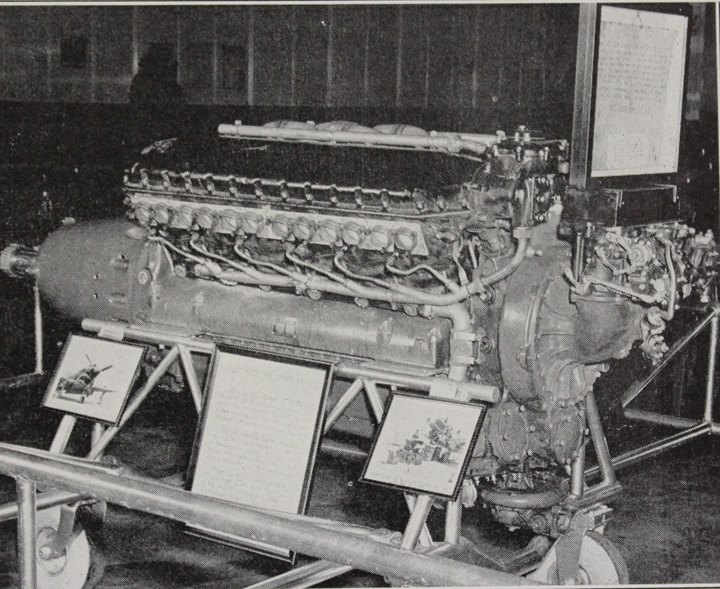

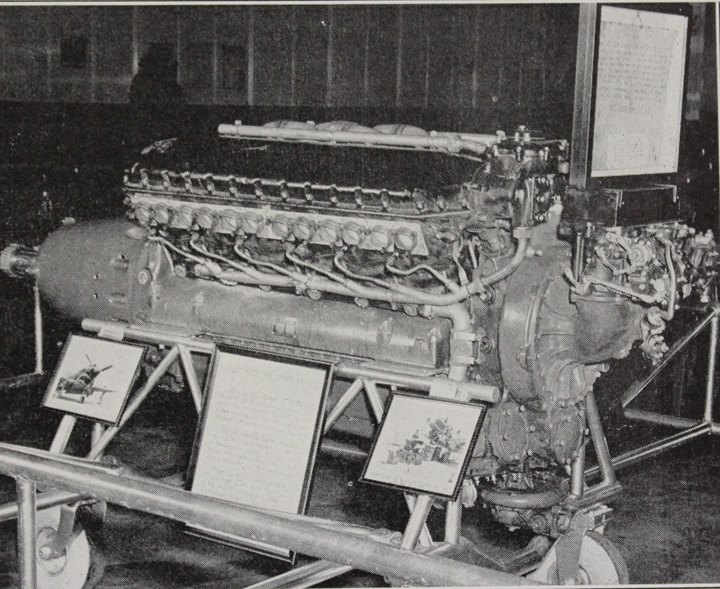

This Allison V-1710 was on display at

Delco-Remy in

February 1942. It came back from Libya with five bullet holes in

the nose housing. The Royal Air Force P-40 Tomahawk was able to

land safely.

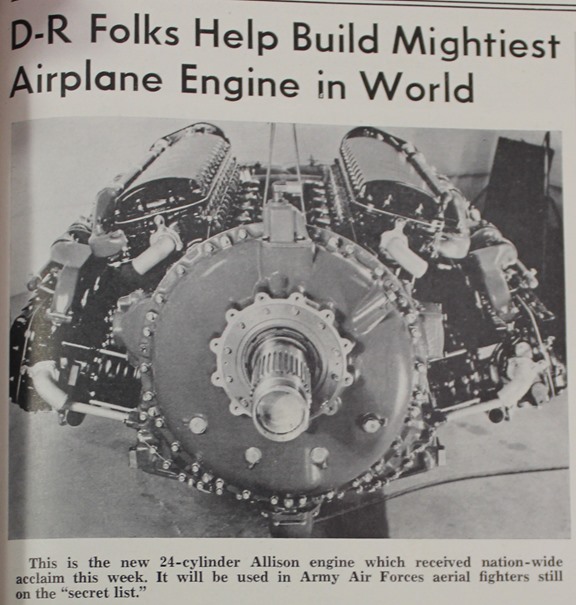

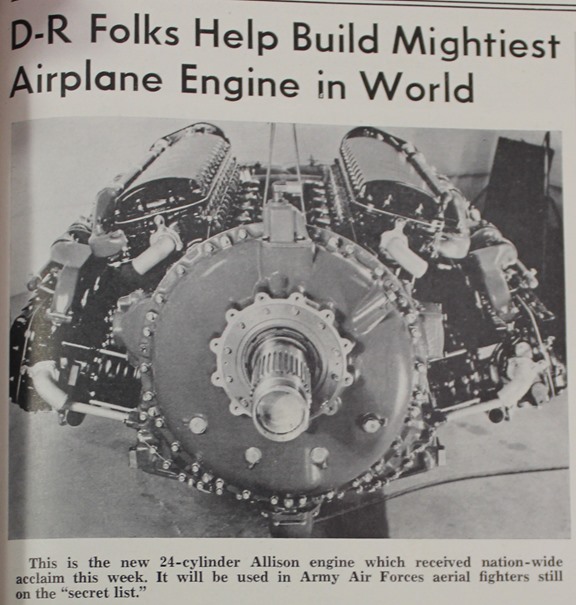

This is the Allison V-3420 engine as shown

in the 'Delco-Remy Clan' dated June 2, 1944. Only 160 were made,

of which four

were used to replace the R-3350 engines on a test B-29. The coming

of jet propulsion doomed this engine. Delco-Remy Plant 7 provided

many of the Aluminum castings for the limited run of the engine.

From the March 9, 1945 'Delco-Remy Clan.'

From the June 1, 1945 'Delco-Remy Clan.'

Bedford,

IN: It was announced in the August 14, 1944, issue of the

'Delco-Remy Clan'

that Delco-Remy had purchased the Salem and Walters Mills and the

property of the Indiana Lime Stone Company in Bedford, IN. The new

plant became the Bedford Foundry Plant of the Delco-Remy Division.

The complex consisted of two mill buildings totally 140,000 square feet

and an office building. It, along with plant 7 in Anderson,

produced aluminum castings for the Allison aircraft engine.

According to the March 9,

1945 edition of the 'Delco-Remy Clan,' Bedford had received new contracts

for increasing production on the Rolls-Royce aircraft engine. This

implies that Bedford had already been producing casting for the Packard-built Rolls-Royce V-1650 Merlin engine. This is the only reference

I have ever seen that Delco-Remy was supplying castings to any other

aircraft engine manufacturer besides Allison. The Packard-built

Merlin engine was the most important and best engine used in an Army Air

Force fighter during World War Two. It made the P-51 Mustang into

the best Army World War Two fighter aircraft.

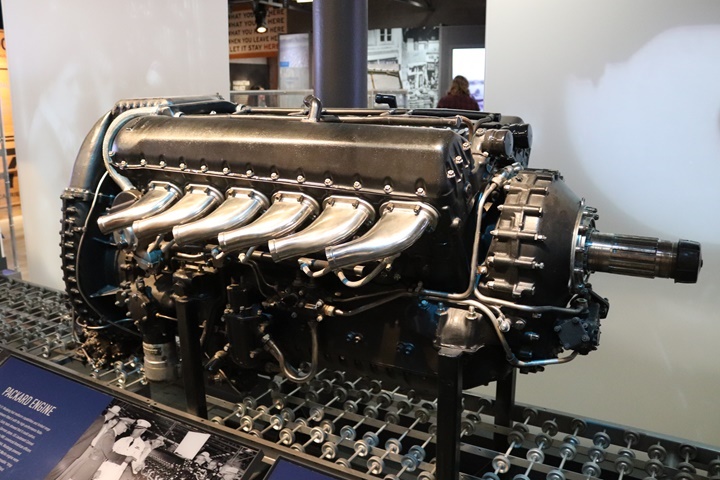

This is a Packard-built Rolls-Royce Merlin

V-1650 aircraft engine. Delco-Remy's Bedford plant produced

castings for this engine. There may not have been much publicity

for this within the General Motors organization, as this was a direct

competitor to the Allison V-1710. The Merlin was also a better

engine than the Allison, which was no doubt an embarrassment to Allison

and General Motors. Author's photo added 5-8-2020.

Kings Mill, OH:

On April 28, 1944 it was announced that the U.S. Navy had taken control

of the former Kings Mill Army Ordnance plant in Kings Mill, OH, and that

Delco-Remy would build cranking motors for diesel powered landing craft.

By the end of the war, in just a year's time, the plant had produced

64,000 naval cranking motors and 375,000 switches. This was done

with a work force of 900 employees.

Before Delco-Remy took over management of the plant, Remington

Arms produced ammunition in it until March of 1944. The .30

carbine ammunition being made in the plant could not be produced in the

quantities needed and was moved to a larger plant. Then the U.S.

Navy took control from the U.S. Army. Delco-Remy tooled up the plant in 60 days for the

production of naval cranking motors and switches for landing craft.

Currently, the former location of

the plant is contained within the grounds of an Army Reserve Center.

|