|

History

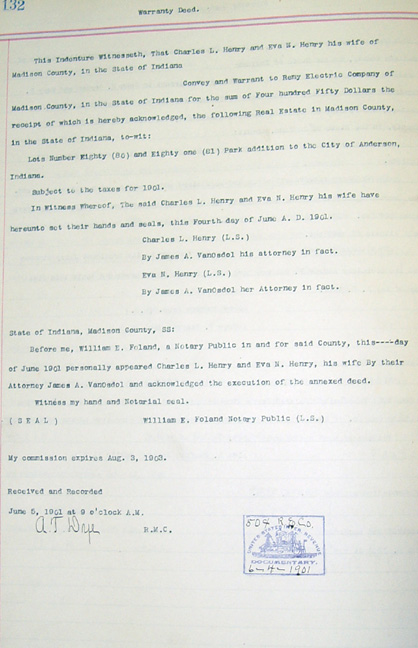

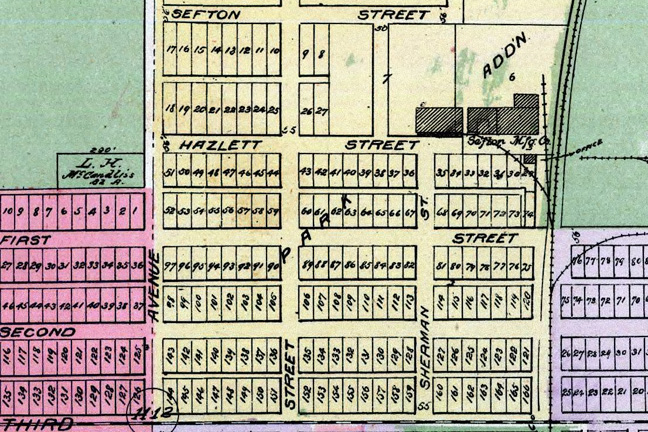

1897 - Next they moved south 2 &1/2 blocks to the west side of Meridian Street between the 14 and 15 Streets. 1901 - Success in the manufacture of dynamos and magnetos several automobile makers allowed them to move to Either lots 80-81at the SE corner of First and Sherman Streets or to Second and Hendricks in Anderson. Take your pick. Research done by Brian Mulcahy indicates that while they had purchased the property and were listed in the phone book at that location, there is no tax record of any improvements to the property that would have been recorded when buildings were constructed. In the 1927 Delco-Remy Brochure "A Trip through Delco-Remy Plants" states that in 1899 the operation moved to Second and Hendricks. See details for all below.

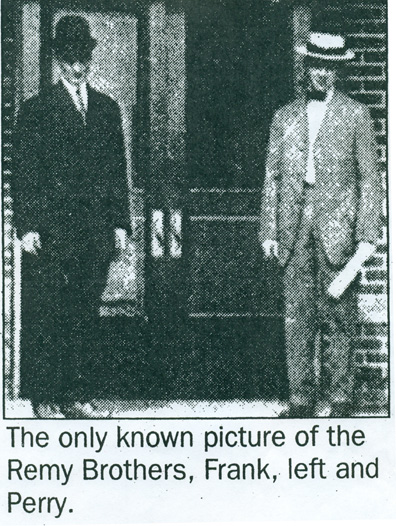

Perry and Frank incorporated to become the Remy Electric Company during which time they developed a high tension magneto that was installed on the 1905 Buick. 1902 - The Remy Brothers employed 15 persons and were a supplier to Columbia, Winton, Sterns, Haynes, Apperson and Stevens-Duryea. 1906 - By 1906 the First and Sherman operation had occupied all of the space and the Remy Electric Company needed to expand and therefore purchased Lot 56 in the 24th block of Columbus Ave. This lot was bounded on the south by the railroad tracks and on the north by a line extending west from just south of 24th Street. The western boundary was Noble Street and Columbus on the east side. The purchase date was May 23 of that year. 1908 - Construction begins in stages on what would become the Plant One Complex. It will finally be completed in 1929. One of the first structures built is the engineering building which later becomes the Plant One school rooms. See the Plant Photo Page for more on the growth of the complex. 1910 - The Remy Electric Company put out an excellent promotional booklet. See our Moments in Time Page to view this excellent look into Remy over 100 years ago. 1909 - 22,000 Model L magnetos were manufactured with 50,000 Model S and T magnetos being produced the following year. 1911 - The Remy Brothers sell the business to Stoughton Fletcher of the Fletcher Savings and Trust Company of Indianapolis, IN. At this this time battery ignition technology was replacing magnetos as the ignition of choice on the automobile. Due to the fact that the brothers had never learned to delegate authority in the organization and the demands on time it consumed, they were pressed to both run the expanding company and develop the new ignition type to stay in business. Hence they decided to sell the business. Between them they received $271,000 which is the equivalent of $6,162,219 in 2009. Mr. Fletcher reorganized the company and hired outside engineering expertise to meet the challenges of the changing market. The Remy Electric Company lost the Buick ignition business with problems with its Model RL magneto, which was the last of this product line for the company except for service business. (Mr. Fletcher went bankrupt after WWI. At the request of the government he invested his own money to supply marine engines for the military. However, the war ended before he could recoup his investment. He later ended up bellhop in California and died a pauper. During the WWII the government built many plants and then leased them to companies such as DR had in Kings Mills, OH, [see 1944 below] because companies were fearful of investing huge amounts of money for a limited payback along with being stuck with unused facilities after the war was over.) 1912 - The Remy Electric Company produces its first self starting cranking motor along with development work beginning on battery ignitions and generators. 1914 - In 1914 the company was producing generators, magnetos, combined starting motors and lighting generators, starting motors, ignition distributors, coils, switches, steam driven turbine generators for steam locomotives and locomotive arc and incandescent lamps. 1916 - United Motors under the leadership of W.C. Durant purchases the Remy Electric Company. At the same time it also purchased the Dayton Engineering Laboratories Company (Delco) in Dayton, OH which until now had been a competitor to the Remy Electric Company as it had invented the first automotive self starter in 1911, a year before Remy came out with one in 1912. Delco also was producing ignitions and generators. Both organizations continued on with their product lines as separate divisions of United Motors. The earlier work by The Remy Electric company starting in 1912 was successful and in 1916 the company produced 41,000 generators and 150,000 ignition distributors. 1918 - United Motors is purchased by General Motors. The GM Division Remy Electric Company is still competing against the GM Delco in Dayton, OH. Remy had 10,000 employed at its Columbus Avenue operation.

During WWI The Remy Electric Company provided

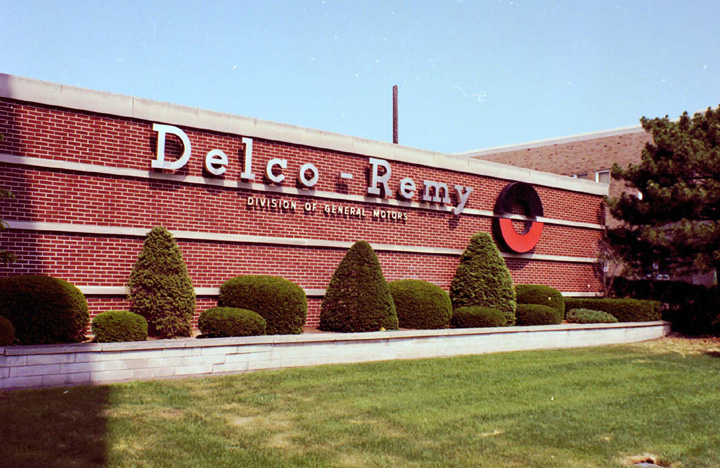

electrical parts for trucks that were being used by the military. 1919 - The first section of Plant One is built. This would have been the east-west section which went all the way to Columbus Ave. When the second north-south section was completed in 1929 it was a massive, L-shaped structure that dominated the skyline of south Anderson and was the Divisional Headquarters of the Division until 1994. Plant One was the symbol of the dynamic character of the Division. 1920 - The Remy Electric company organizes the first employee suggestion plan. After being purchased by GM the suggestion plan was adopted by GM on a corporate wide basis and known as the GM Suggestion Plan. The Remy "Clan" is published for the first time. A safety committee is initiated. 1923 - The Remy Electric Company becomes the world's largest manufacturer of automotive electrical equipment. American Rotary Valve (Arvac) is purchased to produce cranking motors. More land is purchased south of the Columbus Avenue complex for expansion. 1924 - Remy purchases the Klaxon Horn business in Newark, NJ and moves the equipment to Plant 1. Horns would be manufactured by DR later in Plant 7 and then 10 until the business was sold in the late 1990's. 1925 - The manufacture of Nizer fractional horsepower motors begins but is sold to Kelvinator some time later. Remy begins production in Muncie, IN of automotive tail and side lamps. The location of plant later became the site of the Muncie Trade school and was not the same plant or location as the battery plant. 1926 - September 1 the Dayton Engineering Laboratories Company (Delco) and The Remy Electric Company are merged into Delco-Remy with all production of automotive electrical products coming to Anderson, IN. This decision to move all of the electrical products to Delco-Remy Anderson was pivotal and extremely important to the Division and Anderson. From data we have gathered it appears that Delco in Dayton actually had a larger customer base and product line than Remy. See our 1925 United Motors Service Parts Catalog page for more details on this momentous decision for not only DR but the city of Anderson. The Plant openings of Plants 4, 6 and 2 would have provided the capacity to run the product lines brought over from Dayton and accelerate the growth of Remy. Without the Delco product lines these Plants may not have been needed or built. It could be Remy would have ceased to exist as an independent division or disappeared all together. With this acquisition DR had a manufacturing plant in Dayton, OH at least until 1929 when it became Delco Products that employed 2,500 employees. This also correlates with the findings at the RE Olds Transportation Museum in Lansing, MI where several DR products have ID tags with both Dayton, OH and Anderson, IN listed as manufacturing locations.

Plant 4 opened on January 28. Plant 6 on May 28. When Plant 6 opened a circus / open house was held inside the building to celebrate the event and the general public was invited and allowed to attend at no cost. Door prizes of automobiles, radios and refrigerators. Among the guests at the Plant 6 Grand Opening was GM President Alfred P Sloan. One of the main reasons for the event was to demonstrate to the GM staff that there were still plenty of potential workers available in the area to staff further expansion. 48,432 persons visited the event. See our Plant Photos Page for a photo of the event and our video page, 1983 A Year to Remember for actual film footage. The following facts about Remy in 1926 were taken from a handout given to everyone who attended the Plant 6 Open House on May 28. Total employment was 4,497

consisting of 2,989 men and 1,508 women.

Products that are mentioned in the handout that were not given production numbers: Relays, Wiring Harnesses, Cowl and Tail Lamps, Stentor Autophones and shipping boxes. The Stentor Autophone was apparently used in Limousines to replace speaking tubes and was described as a loudspeaker telephone. There is no information on whether DR purchased this business or was building the units under license. 1927 - Plant 2 opens on July 23 and begins to produce coils and ignitions.. Delco-Remy begins manufacture of shock absorber at the former Dayton Engineering Laboratories Company Plant in Dayton, OH. In order to begin the production of shock absorbers GM purchased Lovejoy Shock Absorber Company of Boston, MA when the Remy designed product violated some of Lovejoy's patents. This became Delco Products Division of GMC in 1929. 1928 - Production of Blossom Coincidental Transmission and Ignition Lock begins for Pontiac. This may have been an earlier predecessor to the Neutral Start Back Up switch. Guide Facts and Mis-Facts - GM purchases the Guide Lamp Company in Cleveland, OH in late 1928 and Delco-Remy is given the responsibility of managing the new acquisition. However, beginning in January of 1929 Guide Lamp Division of GMC is created and takes over the former DR Plant 3 or Arvac Plant on West 25th Street. The production of DR cranking motors is moved to Plant 8. DR only had responsibility for Guide for two to three months in what 80 years later looks to be holding action by GM Corporate offices. Unfortunately there is some misinformation that is not historically accurate about the time that Guide spent under DR control which was only 3 months maximum in late 1928. According to a publication on the history of Guide Lamp that was published in 2011, it states that DR took control of Guide in 1923 and between 1923 and 1929 when it became a separate division of GM were "The Lost Years" for Guide. Nothing can be farther from the historical truth! I have researched the newspaper files at the Anderson Public Library and the first article in the Anderson Daily Bulletin that mentions Guide being purchased by GM is November 7th, 1928. In the article it states "the Guide Plant, which was acquired by the Delco-Remy Division several days ago, is to be operated separately, with financial control remaining in the Anderson offices..." The article goes on to describe who was going to be in charge of Guide in Cleveland and that the Guide executives were going to be coming down to Anderson to review and understand how DR did business. If Guide had been acquired by GM for DR in 1923, I don't think the Guide executives would have waited or been given 6 years by Delco-Remy management to come to Anderson to see how DR ran its business. In the November 30th, 1928 edition of the Anderson Daily Bulletin, just 23 days after the initial Guide article in The Bulletin, there is an article that that describes the announcement by Alfred P. Sloan, Chairman of GM, on the creation of two new divisions from within the Delco-Remy organization. One was the creation of the Delco-Products Division in Dayton and the other was the Guide Division. It should be noted that at the time General Motors was in the process of purchasing outside companies such as Guide to have complete vertical integration of the all of the parts needed to manufacture an automobile. Guide was just one of many brought into organization that way. Delco-Remy management in my opinion was just be used as temporary location to have it managed while GM worked on getting its long term structure in place. In any event, Delco-Remy only had control of Guide for a maximum of three months, not six lost years. Copies of the newspaper referenced above can be found in our Moments in Time page. There could be several reasons that the author of the Guide history became confused and thought DR had control of Guide for several years:

Some development work done on radios which is then turned over to the GM Radio Division in Dayton in 1929. However, due to anti-trust action GM had to divest itself of ownership along with RCA in GM Radio. Plants 5 is built as a state of the art grey iron foundry. Plant 8 opened on July 12, 1928. The Seabury Brush Company was purchased. The Muncie Battery Plant, Plant 9, a former Durant automobile manufacturing plant, begins production as DR gets into the battery automotive battery business. This would be a business it would stay in when as part of Delphi Corporation it was sold to Johnson Controls in 2004. In 1928 the current suppliers of auto batteries, Willard, Exide, USL and Presto-Lite, were selling batteries to the OEMs as loss leaders in order to have a presence in the aftermarket business which was profitable. DR was able to development manufacturing processes that produced batteries that met the current OEM prices and still make a profit. This was the beginning of what was 76 year business line. Anderson was offered the opportunity to have the battery plant but the town fathers turned down the opportunity because the amount of electrical power was beyond the current capacity of the coal fired electrical plant along the White River. At that time proceeds from the power plant that was supplying the many industries in Anderson resulted in no taxes to the citizens of the town. The former vacant Durant auto plant in Muncie, which originally was the Interstate Auto Company, produced the Sheridan Automobile in 1921-22. If the battery plant had been built in Anderson it would have been built at the DR baseball diamond at 29th and Noble Streets. This later became the addition to Plant 8. 1929 - Bu-Nite Piston Company of Indianapolis, IN was purchased in February and moved to Anderson. North-East Electric Company of Rochester, New York was purchased and consolidated within DR operations in Plant 1, Department 21. The product line of North-East was large starting motors and this was the beginning of the heavy-duty starter business for Delco-Remy. Also in 1929 DR requested GM Research Labs to run tests on several types of in car heaters vs. commercial product in production. The tests were run but apparently it was decided not to get into the business. The south end of the Plant 7 Box Plant in Anderson burned on April 3. This was the second Plant 7 in DR history. 1932 - The remainder of Plant 7 Box Plant burned in a fire on December 13. Both fires in this plant were not recorded in any official DR history. 1933 - Packard Cable Company was purchased and production was moved to Plant 8. This was later moved to Warren, OH and became the Packard Division of GM. A box plant was built in Anderson to replace the Plant 7 Box plant that burned in 1929 and 1932. No location has been given that can be found to date. However, it is the author's premise that this plant was what later became Dept. 137 Salvage. There is no known record of the Salvage building being built in any of the historical records that I have come across. Also the location of Dept.137 just to the north of Plant 5 is in the same area as the previous Plant 7 Box Plant. Based on this we are going to say the 1933 Box Plant and the Salvage Building are the same. 1936 - Additional floor space is added to Plant 8. Battery production starts in the Bloomfield, NJ Battery Plant. GM buys the Crosley Radio Plant in Kokomo, IN and Delco-Remy manages the operation until it becomes the Delco Radio Division. 1937 - Plant 3 is built for the production of cranking motors which come over from Plant 6. 1938 - The UAW winds bargaining rights for DR hourly employees. Of the 6,738 employees eligible to vote, 6.424 voted in the election. 3,894 (61.9%) voted yes and 2,398 (38.1%) voted no. Sixty-three ballots were blank, 15 voided and 54 challenged. With the election of the UAW as the representing body for the workers, 29 District and Alternate Committeemen were elected along with 7 Shop (Zone) Committeemen. The Districts were allowed 3 hours per day and the Shop (Zone) Committeemen were allowed 4 hours per day to attend to union business. 1940 - Plant 7 is built in 71 days at the end of the year and was originally known as the Aluminum Foundry. It was built with the intent of providing Al castings to Allison in Indianapolis for its V-1710 engine. DR provided over half the the castings needed for the 69,305 V-1710 engines built. The Aluminum Foundry was originally only the south end of the plant where switches and horns were built in later years. The north end where Al die cast and thermoset molding were performed in later years was added after WWII. 1941-1945 WWII - After the US enters World War II in December of 1941 DR converts to 100% war production and produces 673 different products for the war effort during this time period. 40,000 different part numbers were needed to make these 673 models. Plant 10 is built in 1941 for the assembly of aircraft magnetos and to machine castings produced in Plant 7 for Allison. It is an air conditioned building. Bloomfield, NJ battery plant is transferred in 1942 to the Eastern Aircraft Division of GM and builds electrical wiring and hydraulic tubing for GM built Grumman FM-1 and FM-2 Wildcats and TBM Avengers. Aluminum foundries are purchased in Bedford, IN and Yellow Springs, OH in 1942. The Bedford Plant was the first Delco-Remy Plant 11. The Midwest Plant in Anderson, IN is purchased in 1943 for the packaging and shipping of civilian auto parts. A plant was leased from the US Navy in Kings Mills, OH in 1944 for the production of heavy duty starting motors for landing craft. It was returned to the Navy after the war. Products produced during the war included: starting motors, generators, voltage regulators, junction boxes, distributors, coils, batteries, Al castings, grey iron castings, tubing for electrical conduit, fuel lines, brake lines, air lines, and refrigerator lines, switches, magnetos, automatic aircraft controls, Sperry auto pilot, 20mm shell bodies, and solenoids. The various products were used by all services in ground, air and marine applications. Hence the phrase: "Wherever Wheels Turn or Propellers Spin..." Go to our "Moments in Time" Page for the complete story of DR during WWII. 1946 - New Brunswick, NJ Battery Plant built. 1947 - Delco-Remy Service School established. 1949 - Delco-Remy instituted a half hour lunch period replacing the previous hour lunch. In order to accomplish this a central kitchen was created in Plant 2 which then provided the prepared food to the plant cafeterias. Plant Two also provided cafeteria services for Plants 4, 6 and 8. 1950 - Plant 10 adds floor space on the east end. 1951 - Plant 3 expanded. 1952 - The second Plant 11 is built for the manufacture of jet engine parts for Allison. In 1962 it begins the production of the Delcotron alternator for passenger vehicles which stays in the plant until it closes in the early 2004. It was razed in 2006. Converted automobile industry from 6 to 12 volts which was no trivial task. For many years the auto industry has deliberated about going to 24 volts but no one wants to take the first step. 1953 - Anaheim, CA Battery Plant is constructed. 1954 - Delco-Remy introduces musical notes horns. Four notes become the standard for GM: F, A, D, and C. 1956 - Olathe, KS Battery Plant is built. With the construction of this facility DR now has battery plants that run from the east to west coast. Batteries are expensive to ship due to their weight and the DR battery locations were not only close to GM car assembly plants in each area but could also ship out aftermarket batteries in a more cost effective manner. The 214 acre Killbuck Employee Park is opened. 1958 - The 100 millionth battery was produced in January with a ceremony commemorating the event at the new Olathe Plant. First to introduce the Delcotron Alternating Current Generator. Production would begin 4 years later in Plant 11. Introduced the first Transistorized Voltage Regulator. This was just ten years after the transistor was invented by Bell Labs in 1948. Advanced Engineering Department created. 1959 - Plant 15 built for remanufacturing and service parts packing and shipping. Plant 16 built to house tooling, maintenance and central stores operations. Plant 3 expanded for the second time. 1960 - DC-250 Battery introduced for the Heavy Duty market. Killbuck Park Lodge is opened. Several other Delco Divisions had similar lodges in Kokomo and Dayton. The one in Kokomo for Delco Radio/Electronics was of a similar design to the one at Killbuck. 1961 - DR is the first to introduce the magnetic pulse distributor. A similar design would end up in the High Energy Ignition that was introduced in 1974. 1962 - Delco-Remy is the first to introduce brushless charging systems which go into production on the 25-SI generator. Silver-zinc batteries are developed for use in the US Air Force Minuteman Intercontinental Ballistic Missiles and are produced in the basement of Plant 11 in what was designated Plant 21. The "Road Gang" consisting of matched starting motor, generator and battery is developed to meet specific heavy duty over the road and off road industry needs. Plant 17 is built to expand manufacturing capacity for heavy duty starters and motors. Plant 11 begins production of the 10-DN Delcotron. Plant 18 is built as the Delco-Remy Product Engineering Center. This was of a design used at several GM locations. Plant 10 at Delco Radio/Electronics and the Administrative and Engineering Building at Packard in Warren, OH are nearly identical. It is my understanding that Plant 10 in Kokomo is to be razed. The building at Warren is a two story. 1964 - Plant 10 expands again, this time on the north side with the ramp up to the plant floor and offices. 1965 - The Muncie Battery Plant produced its100 millionth battery on September 13. The Delco Energizer Battery was introduced which is the first to replace rubber battery cases with plastic cases and one piece top covers. Also included in the new design are through the wall cell connectors and the Delco Eye for determining battery charge state. The battery had 16% more power than previous designs. Delco-Remy total employment including the five battery plants reached 20,917 employees. 1966 - DR was the first to introduce a Capacitive Discharge Ignition System. DR provided silver-zinc batteries for the GM Electrovair program which was a Chevrolet Monza electric vehicle. DR participated in the GM Electro Van Program. Plant 17 gets an addition that doubles its size. 1968- The Killbuck Golf Course opened. 1969- Delco-Remy introduced the first Dial-A-Curve Ignition System The Delco Freedom Battery was introduced which was a maintenance-free, lead calcium design. DR participated in the GM512 "Shopper Car" project by providing batteries and DC motors. 1971- Pontiac was the first GM vehicle line to receive the Freedom Battery. JC Penny sold the battery for the aftermarket. DR introduced the Unitized Ignition System. 1972 - Plant 20 was built. Plant 19 was built as an OEM shipping plant for all of the Anderson Plants. It features an automated stacker system for the storage of finished product. Delco-Remy Anderson was at its peak in Anderson until 1984 when plant 2, 4, 6 and 8 come down. 1973 - The High Energy Ignition goes into production in Plant 20 as a 1974 model year product. Construction began on the Fitzgerald battery plant. This was plant 22. 1975 - The Delco Freedom Battery becomes standard on all GM vehicles. Plant 25 in Meridian, MS is purchased for the production of 5-MT motors. This was the beginning of the end for Delco-Remy in Anderson. DR had purchased and owned at that time all of the land that is now part of the Hoosier Downs Racetrack and Casino. However, when approval was sought from GM for increased production of starting motors in Anderson on that property, it was refused by GM management due to the size, power, and attitude of the DR UAW. So the production of the motors went to Meridian. Magnequench 10 years later would be a short lived exception to this rule. 1976 - Delco-Remy introduced the MISAR (Micro Processed Sensing and Regulation) which was the first digital computer controlled ignition system. This was the forerunner of the ECMs that now control the engine management on all vehicles. Delco Electronics took over the operation in 1978 and moved it to Milwaukee, WI. 1977 - DR was the first to introduce Knock sensors. 1978 - DR produced Nickel-Zinc batteries for 18 Chevettes that were converted to electric drive. Albany Plant was built for the production of high output Delcotrons. The Shreveport plant along with MISAR product line was transferred to Delco Electronics. (DE was good at letting other GM divisions do early development work on electronic products to then take them over when the high production revenues and profits began to accumulate.) 1979 - DR provided lead-acid batteries for 20 full size electric powered GMC vans used by ATT in Culver City, CA as a DOE project that ran until the early 1980's. Plant 35 in Juarez, Mexico and El Paso, TX Warehouse opened. 1980 - Sarreguemines, France battery plant was constructed to provided Freedom Batteries to the European Market. 1981 - The first DR permanent magnet starters were developed. 1983 - Project for Charging System (CS) Delcotrons was announced on September 19. This was a $75 million project with 2/3s of the funding going towards Anderson. Project for $68 million Permanent Magnet Gear Reduction (PM/GR) cranking motors is announced in October. DAC is the first Delco-Remy joint venture which included cranking motor, generator and ignition technology and production. Took over from GM the management and production of the Gennevilliers, France plant for starters, generators and ignition. 1984 - Delkor, a joint venture in Korea is formed. 1985 - Construction on the Magnequench plant in Anderson begins for production of rare earth magnetic powder and magnets. Plants 2, 4, 6, and 8 are torn down. 1986 - Delco Remy is the first to introduce the Direct Ignition System (DIS). A further expansion of the facility in Indianapolis became the Advanced Engineering and Technology Center. Three years of fuel cell development begins. 1987 - DR develops an ignition system for Chevrolet engines to be used in IndyCar Racing. The Division changed from a centralized functional organization to one that incorporated Strategic or Small Business Units (SBU). This was done after a management consulting firm was hired to look at the organization and determine what was wrong and how it could be be fixed. This assumed there was something wrong which may or may not have been the case. But after being paid large sums of money the consulting firm had to make some sort of significant recommendation and the Division was divided into five SBUs: Batteries, Starting Motors, Heavy Duty, Generators, and Ignition and Controls. Each SBU then had its own management structure and its version of the previous divisional centralized functions. This created five different small divisions within the division that over time began to go their separate ways resulting in non standardized procedures for those dealing with them both inside and outside the company. Without the SBUs it would not have been so easy to break up the division in 1994 into one group consisting of Heavy Duty and Starting Motors forming Remy International and the remaining to stay at least for a couple of years with GM until it became part of Delphi. But it sounded like a good idea at the time. Plant 5 Foundry shut down and razed after making its last pore of metal on October 4. 1988 - DR introduced Integrated Direct Ignition (IDI) for Quad 4 Engines. The Intellek sensor family was introduced. 1989 - The Integrated Coil Electronics (ICE) Ignition system is introduced. A Gas Recombinant battery for on-board use in the IndyCar race vehicles is produced. 1990 - Battery plant built in Piracicaba, Brazil. DR began work on the development of electric propulsion drive systems. This would lead to the electric drives on the ill fated GM EV-1 "Impact". The demise of the "Impact" was not technical but due to corporate politics and lack of vision on electric vehicles. 1991 - Built Seixal, Portugal Plant for ICE Ignition production in Europe. Introduced "Optispark" ignition for Chevrolet Corvette. 1992 - Divisional Headquarters moved from the third floor of Plant One to the first floor of Plant 18. (After the move to SBUs there was still a general manager was responsible for the five business units.) 1994- Opened Lithium Polymer battery development center in Indianapolis.

1994 - Delco-Remy Division of GMC

ceases to exist as a its own division with its headquarters in Anderson,

IN and is spilt into two pieces. On July 1st of 1994 the following

product lines were merged with the AC Rochester Division to become the

AC Delco Systems Division with Headquarters in Flint, MI. The

product lines that went into this division were passenger car

alternators, batteries, switches, sensors, solenoids, horns, vacuums,

and ignitions. A month later on August 1st the remaining product

lines of the Heavy Duty product lines and passenger car cranking motors

went to a group of private investors that carried on the name of Delco

Remy or Delco Remy America and is now known since 2004 as Remy

International. |

||||||||||||||||||||||||||||||||||||||||||||||||